5 Industries Impacted by Nylon PA 12 Flame Retardant

One of those advanced materials is Nylon PA 12 Flame Retardant (FR) — a halogen-free, flame-retardant material certified to UL 94 V0 at 2.5 mm. It combines excellent thermal stability, dimensional accuracy, and premium surface finish—all while meeting strict flammability and regulatory standards.

Here are five key sectors where this material excels.

1. Automotive

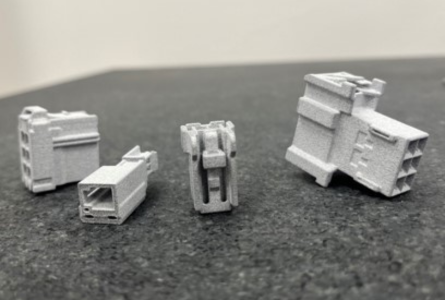

Endeavor 3D took advantage of the material’s capabilities by reverse engineering broken wire harness components inside a car door. Using Nylon PA 12 FR, replacements were 3D scanned, printed, and installed within 24 hours. These connectors, ranging from 25 mm to 74 mm with a wall thickness of 1-2 mm, demonstrated tight tolerances (±0.010 mm) and passed the stringent burn resistance requirements for occupant compartments of motor vehicles.

PA 12 FR car door components

PA 12 FR wire harness connectors

2. Consumer Electronics

PA 12 FR battery holder. Credit: HP

3. Industrial

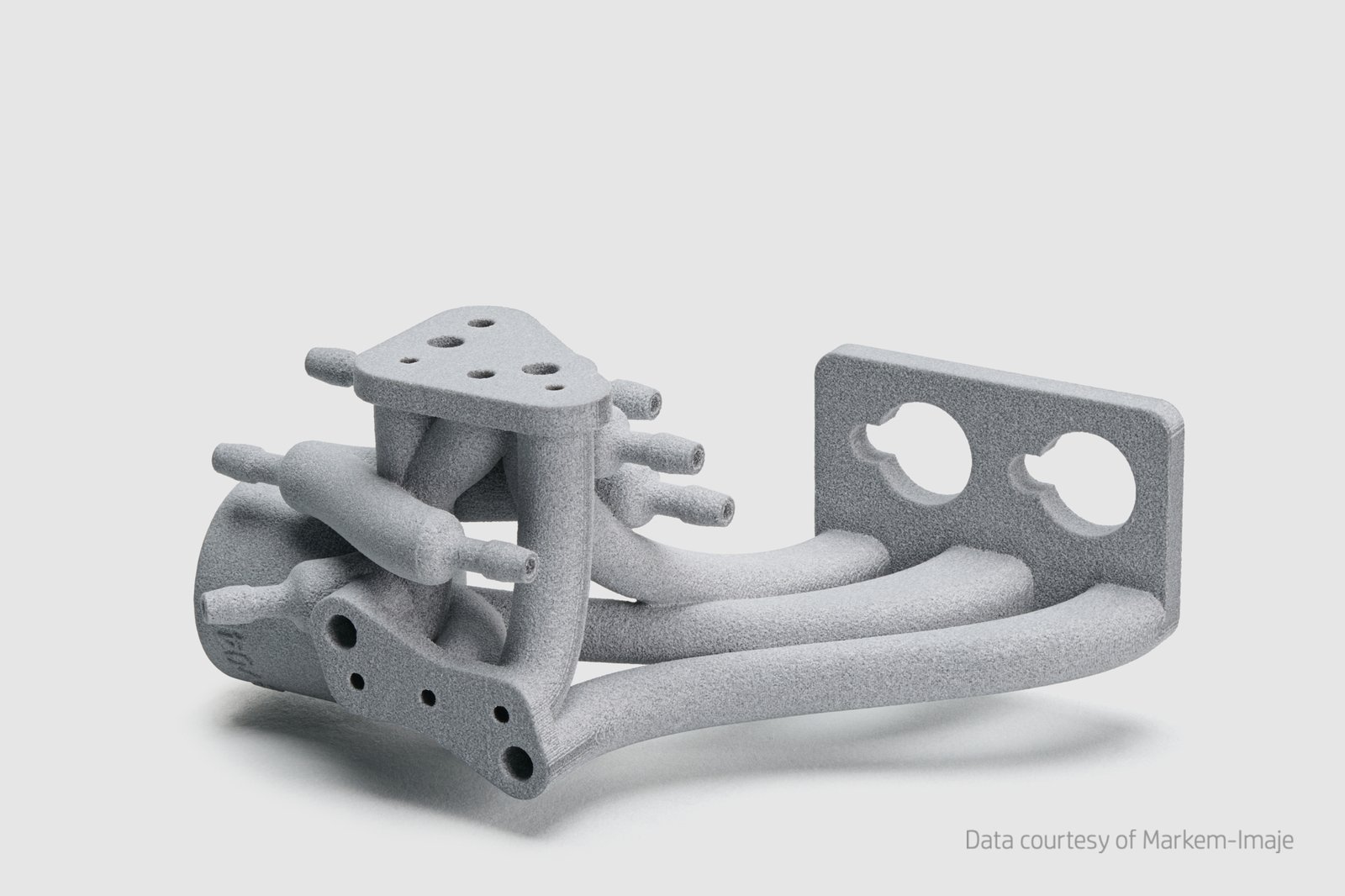

Building on these strengths, HP partnered with Bronymec, an international contract manufacturer, to redesign a set of relay blades. Originally machined from metal, the blades were transformed into a 3D printed solution using Nylon PA 12 FR. By leveraging design for additive manufacturing (DfAM) principles, Bronymec consolidated nine parts into two, significantly improving the ease of installation and lowering production time.

Building on these strengths, HP partnered with Bronymec, an international contract manufacturer, to redesign a set of relay blades. Originally machined from metal, the blades were transformed into a 3D printed solution using Nylon PA 12 FR. By leveraging design for additive manufacturing (DfAM) principles, Bronymec consolidated nine parts into two, significantly improving the ease of installation and lowering production time.

PA 12 FR hydraulic connector

4. Railway

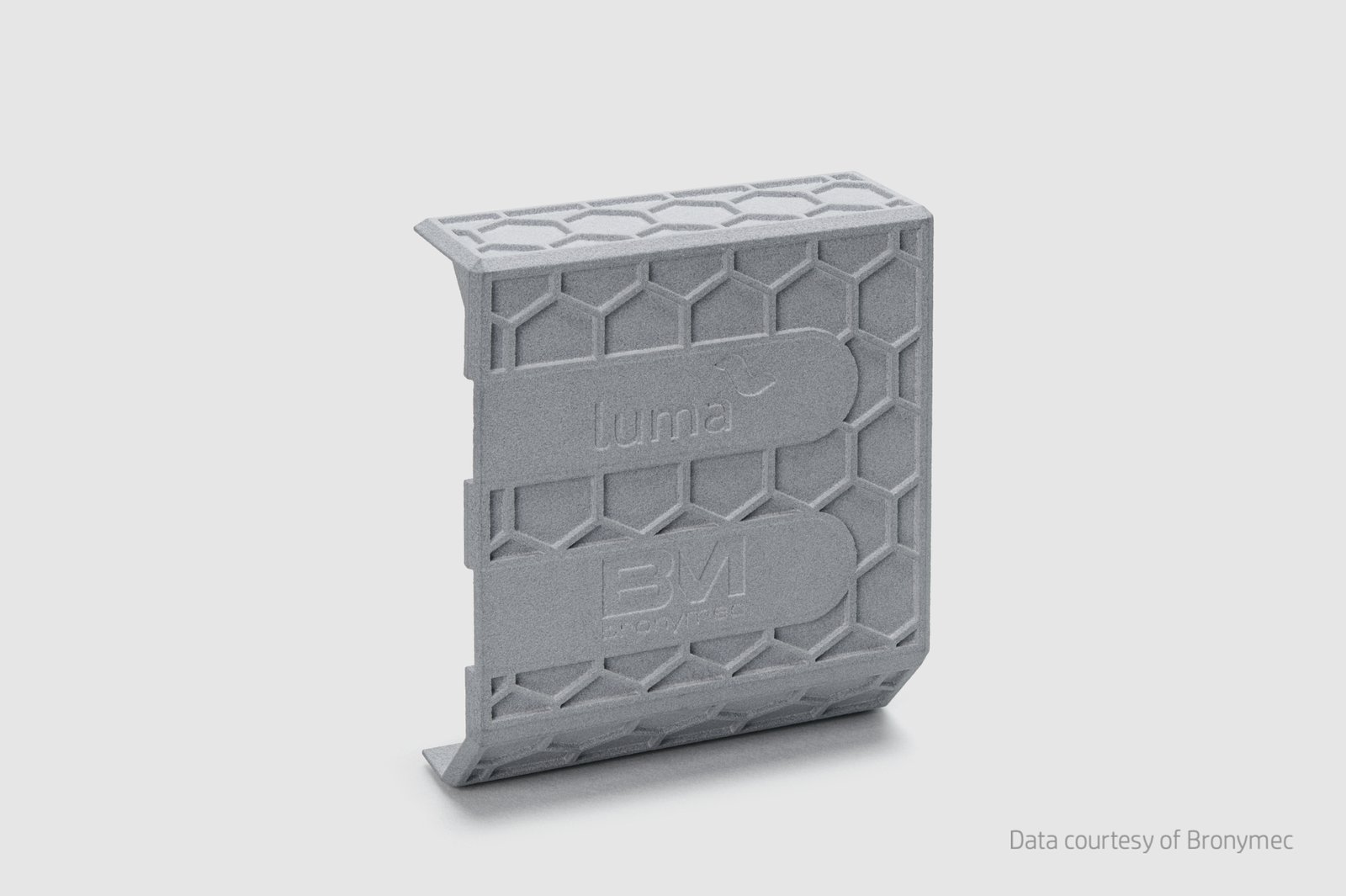

For example, Nylon PA 12 FR is an excellent choice for protective shields that insulate high-voltage electrical components from external elements. Traditional manufacturing methods for these types of parts can be costly and time-consuming due to tooling requirements and extended production cycles. By leveraging 3D printing with Nylon PA 12 FR, manufacturers can significantly reduce production costs, speed up delivery times, and eliminate the need for expensive tooling.

PA 12 FR protective shield

5. Robotics

Dielectric strength (PA 12 FR = 7.6 kV/mm) measures how well a material can withstand electrical stress without breaking down. So why does this matter in robotics? Many robots contain dense assemblies of wires, batteries, and PCBs within tight housing spaces. Materials with high dielectric strength reduce the risk of short-circuiting and arcing between conductive paths.

Surface resistivity is also a crucial property for robotics because it helps control static electricity buildup. When static electricity builds up, sensitive electronics can become damaged, causing interference with sensors or onboard processors. This can lead to false signals in control systems and communication modules.

Conclusion

Endeavor 3D is one of the first contract manufacturers in North America to offer Nylon PA 12 FR for production-ready use. Want to explore what PA 12 FR can do for your application? Visit the Endeavor 3D Nylon PA 12 FR material page to learn more or contact us for a free quote.