Our Additive Manufacturing Services

Collaborating with Industry Leaders

Industries

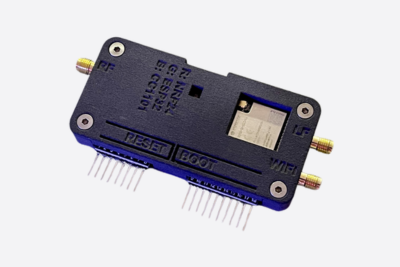

Aerospace & Drones

Enables rapid prototyping and flight-ready bridge production of complex, lightweight components

Automotive

Supports rapid prototyping and low-volume functional parts for traditional, electric, and autonomous vehicles

Consumer Goods

Delivers mass-customized, on-demand prototyping and production parts with premium finishes and fine detail

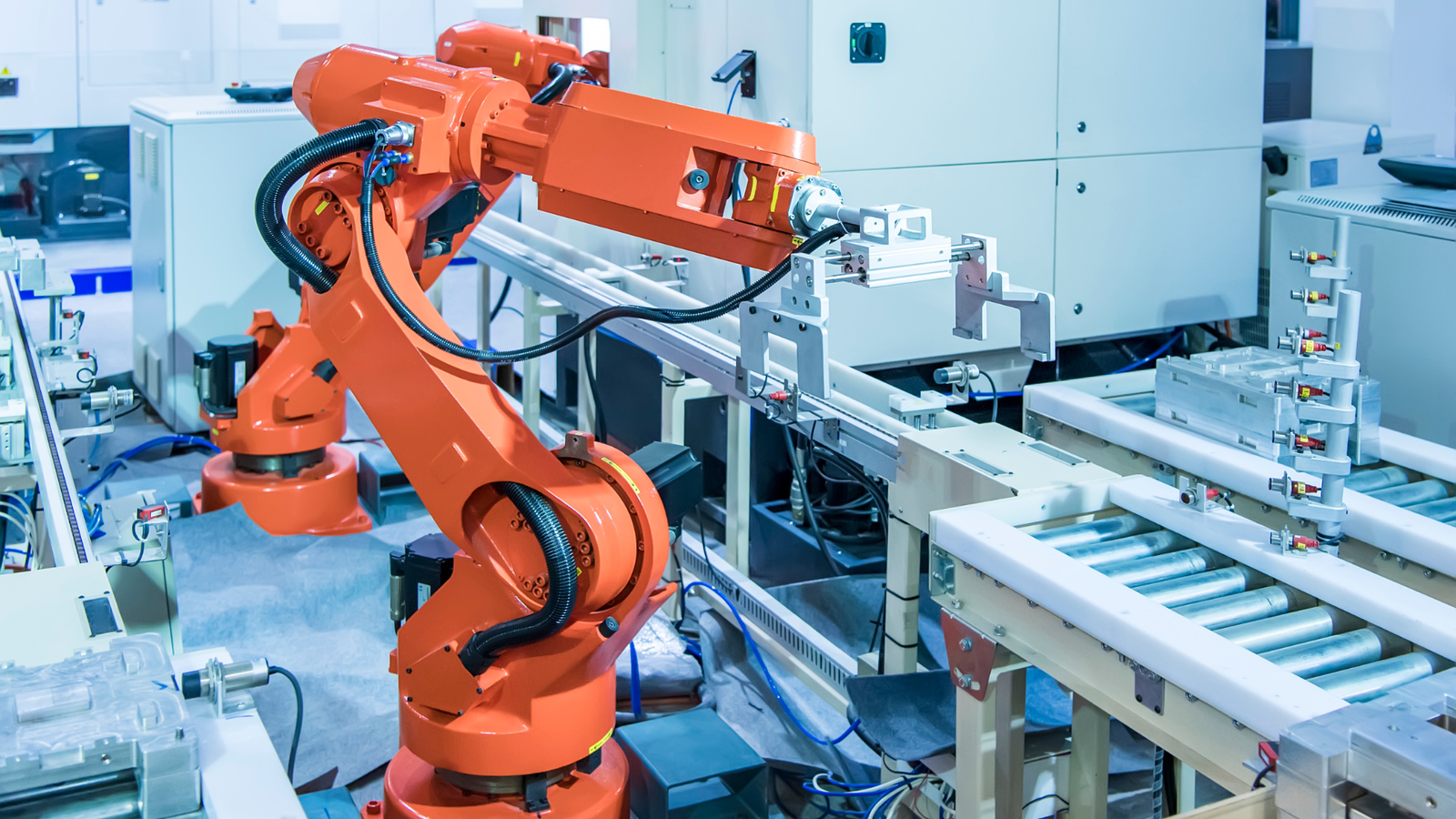

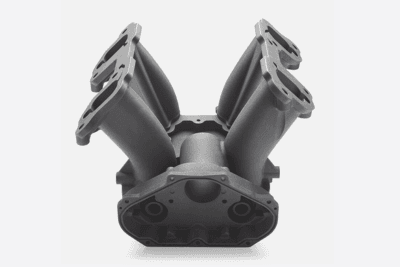

Industrial

Offers jigs, fixtures, end-of-arm tooling, and spare parts to support assembly automation and equipment repair

Medical

Provides patient-specific orthotics and prosthetics, surgical models, and medical devices using biocompatible materials

Robotics

Overcome design constraints and accelerate product development for robotic assemblies and automation systems

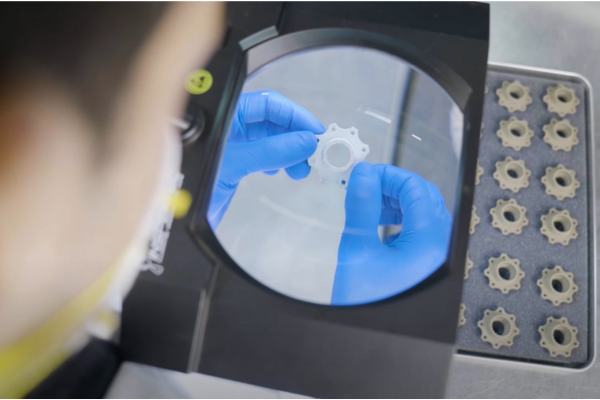

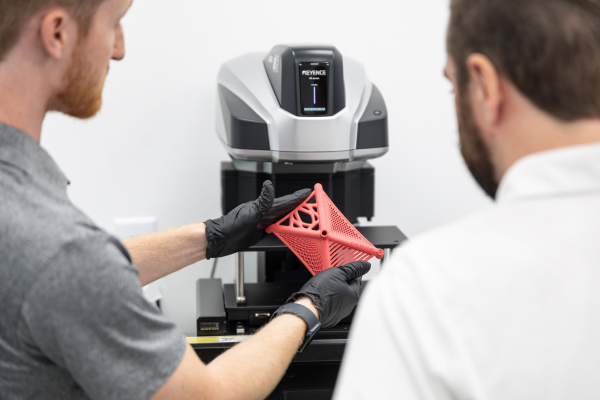

A Commitment to Quality

Endeavor 3D is the largest 3D printing contract manufacturing partner in the southeast United States. We specialize in product design, prototyping, production, quality assurance, and fulfillment services. Endeavor 3D is ISO 9001-2015 certified, ITAR registered and services a variety of industries including automotive, aerospace, healthcare, industrial manufacturing, consumer products, and more.

How to Work with Us

Contact Us

Simply submit your project details for an in-depth review of the full scope of your project.

Collaborate

Development

Shipping

Don’t have a 3D file? We’ll create it for you.

Tailored Solutions at Every Stage of Your Project

Endeavor 3D is committed to guiding your project from initial concept through prototyping to final production, ensuring seamless transitions and top-quality results at every stage of the product lifecycle.

ACCELERATE YOUR IDEAS

- Free Quoting

- Quick Design Iterations & Testing

- HP Digital Manufacturing Partner

- Design for Additive Manufacturing (DfAM)

- FDM 3D Printing

- 2D to 3D File Conversion

SCALE WITH CONFIDENCE

- Market Demand Agility & Scalability

- Lower Capital Investments

- Zero Tooling Requirements

- 100% Part Inspection

- Quality Documentation

- Vapor Smoothing & Dyeing

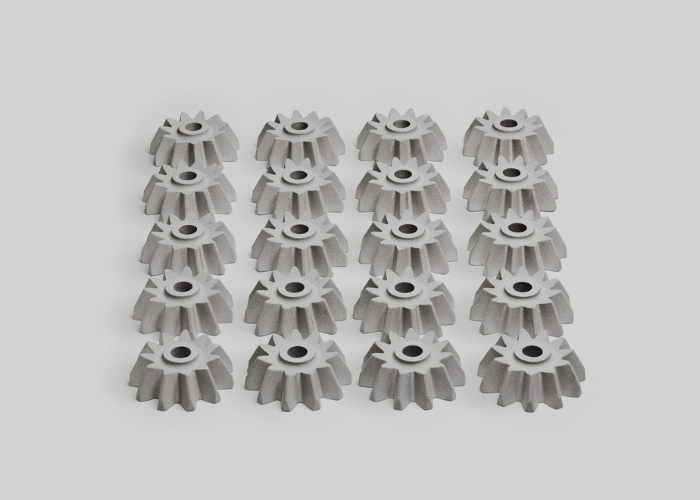

STREAMLINE MASS PRODUCTION

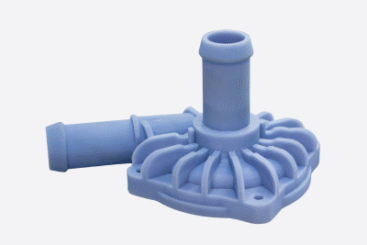

- Lower Cost-Per-Part

- PPAP Quality Services

- Customization At Scale

- Multi Jet Fusion

- Metal Jet

- Automated Post Processing

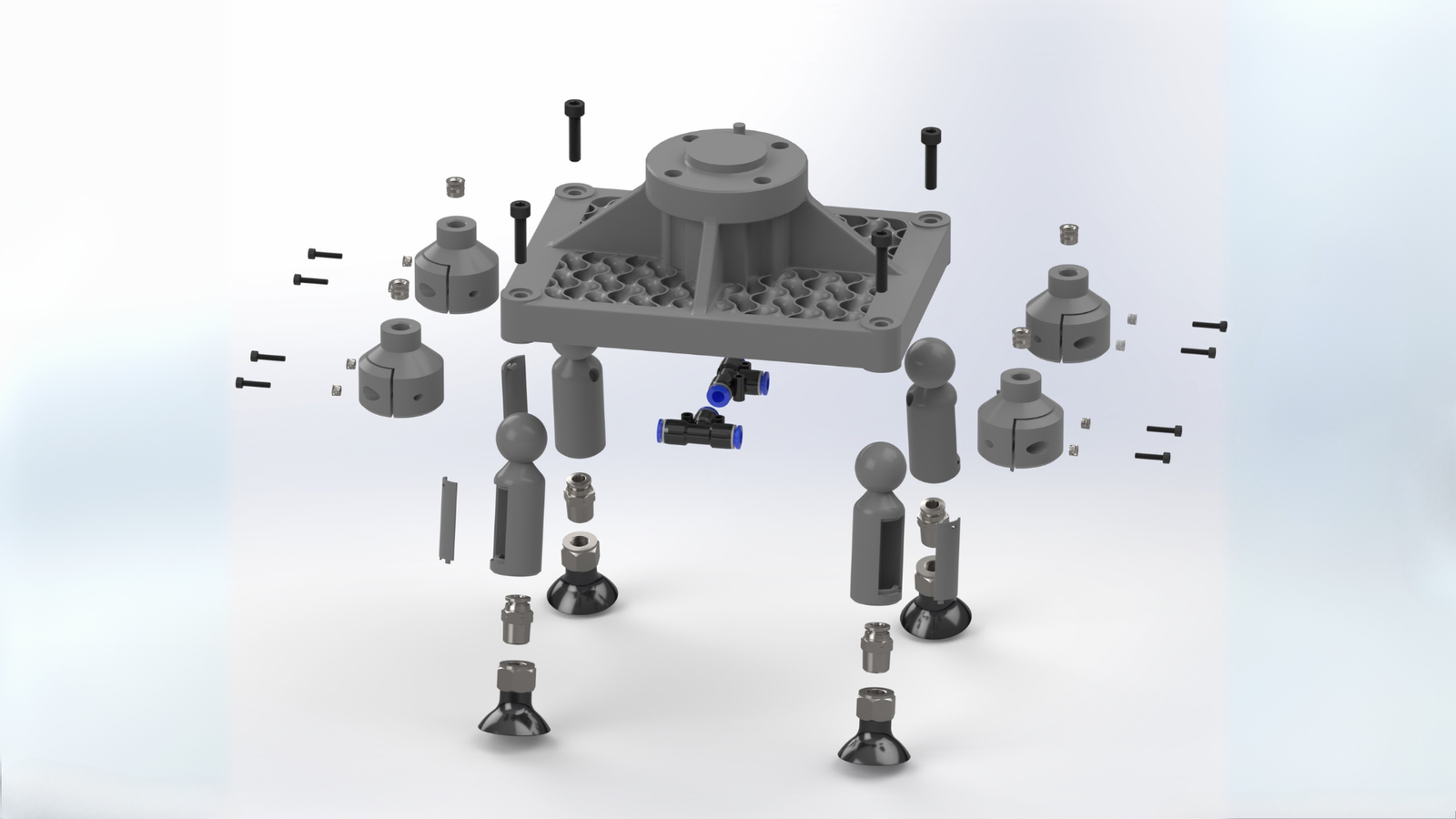

GET CUSTOM JIGS & FIXTURES

- Cost Effective Batch Production

- DfAM For Lightweight And Improved Ergonomics

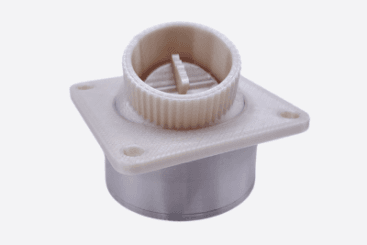

- Polymer And Metal 3D Printing

- Multi Jet Fusion

- Part Consolidation

- Part Assembly

REPAIR WITH EASE

- 3D Scanning For Legacy Part Production

- Minimize Equipment Downtime

- On-Demand Manufacturing

- Reverse Engineering

- Digital Part Storage

- Flexible & Chemically-Resistant Materials