Benefits and Applications of Nylon PA 12

With HP MJF and Nylon PA-12, Endeavor 3D’s additive manufacturing solution delivers important benefits, across a wide range of industries and applications

Spotlight on benefits

While 3D printing with PA-12 offers myriad benefits, there are three that are especially important:

- Strength – HP PA-12 offers superior strength and impact resistance, making it ideal for many types of consumer products

- Chemical resistance – parts made from PA-12 can be made watertight and are resistant to many types of fluids, making it a suitable material for many automotive applications

- Biocompatibility – this unique material is biocompatible for many applications, including orthotics, prosthetics and other medical devices

E3D staff inspects 3D printed robotic End of Arm Tooling

Applications for consumer products

Here are just a few examples of how companies are using 3D printing and PA-12 material to innovate:

- Sporting goods – a wide variety of products, which require strength and durability, including football helmets, baseball bats, and ski boots have been enhanced or newly created with HP PA-12.

Example: The Union Binding Company develops prototypes of their snowboard bindings using HP PA-12 and then tests them with elite athletes. HP PA-12 was chosen for its strength, durability, and lightweight properties

- Toys – Action figures, building blocks and toy cars, which can benefit from other 3D printing capabilities like customization, have been produced with HP PA-12

Example: LookReal manufactures super realistic, personalized doll heads. HP MJF was chosen for its high level of accuracy and superior surface finish

- Eyewear – HP PA-12 has been used to manufacture eyeglasses, sunglasses, eyeglass parts and more.

Example: Horizons Optical developed an end-to-end solution for making customized eyeglasses. HP PA-12 was chosen for its strength, durability, and ability to withstand the wear and tear of everyday use.

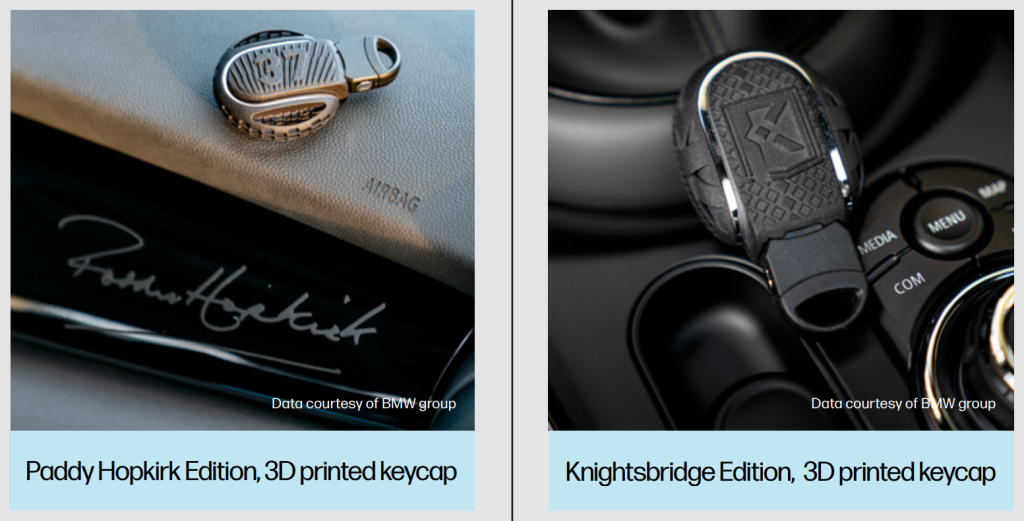

3D printed keycap for limited edition MINI vehicles via BMW and HP

Applications in Automotive

Chemical resistance is vitally important to auto manufacturers as their products are often exposed to gasoline, diesel fuel, oil, coolant, and other liquids. Resistance to these chemicals helps ensure the performance and durability of a vehicle. Here are some examples of how the automotive industry is leveraging the chemical resistance of HP PA-12:

- Manifolds – are used in many types of vehicles, from cars and trucks to motorcycles, boats and more. They generally control the movement of air or fluids, including solvents and other chemicals

- Customized accessories – Accessories are an important differentiator and revenue generator for automotive companies. Customization and personalization can increase their perceived value.

Example: Manufactured with HP PA-12 for Mini and Other BMW brands, these customized keyfobs celebrate limited edition vehicles

- Battery components – As more vehicles move to hybrid and electric powertrains, important new parts must be designed, tested, and manufactured. Batteries and their packaging are central to this effort.

Example: MotoSpirit utilized HP PA-12 to create battery stacks where individual batteries are housed. With 3D printing they were able to reduce weight and improve performance.

Medical device applications

The biocompatibility of HP PA-12 helps ensure the safety, performance and durability of medical devices, and makes it a great choice for many different applications:

- Dental aligners – 3D printing is now the dominant technology in dental aligners and HP PA-12 enables dental molds that are biocompatible and recyclable

Example: Nivellmedical developed an invisible aligner solution that uses HP PA-12 to print dental molds, which are used to produce invisible aligners.

- Orthotics / prosthetics – HP’s PA-12 is a great choice for orthotics and prosthetics because it is strong, durable, lightweight and resistant to sweat and moisture. In addition it’s also safe to wear against the skin surface

Example: iOrthotics developed an direct-to-patient solution that uses HP PA-12 to print personalized foot orthotics

- Testing devices – HP PA-12 has been used to produce a variety of medical devices, including those used for testing. It’s ideal because these devices need to be strong and durable to operate, but also easily sterilizable and biocompatible to avoid patient harm

Example: Everex has developed a new testing device which can indicate abnormalities in the blood. With HP MJF they were able to utilize a more elegant design that requires fewer parts and is easier to assemble.

Now for the rest of the story…

In the previous two articles in the series, we wrote about how plastics are driving 3D printing’s growth and why the combination of HP’s MJF and PA-12 enables easier innovation.

Want to see if PA-12 is right for your application?

HP’s Multi Jet Fusion and unique 3D HR PA-12 material, combined with Endeavor3D’s technology and expertise makes it easy for companies to fully unlock the benefits of additive manufacturing. If you’re looking for a solution that offers new design freedom and lighter weight, but also need a material that delivers a wide range of benefits, from strength, durability, and flexibility, to chemical resistance and biocompatibility…you’ve found it here.

Let’s continue the conversation! CONTACT Endeavor 3D