Soft robotics is a burgeoning field focused on creating robots that mimic the flexibility and adaptability of biological organisms. Thermoplastic polyurethane (TPU) has proved to be an optimal material for this application due to its unique combination of elasticity and strength. TPU enables the construction of soft robotic components that perform complex and fluid movements. This is essential for tasks requiring high adaptability and gentle interaction with delicate objects.

TPU’s flexibility allows robotic grippers to conform to various object shapes and sizes. The compliance of TPU enables the grippers to apply uniform pressure, helping securely grip objects without causing damage. So how does TPU apply enough uniform pressure to grip objects of varying weight? TPU can be engineered to provide different degrees of hardness and softness by adjusting its formulation or structure during the design phase. By fine-tuning the grip strength and control, the gripper can quickly adapt to the object’s shape and position. This adaptation is further aided by the material’s ability to stretch significantly without permanent deformation. This high elasticity allows soft robotic components to bend, twist, and compress, mimicking the intricate movements of biological systems.

An end effector is a component or tool attached to the end of a robotic arm that interacts directly with the environment to perform specific tasks. End effectors are fundamental in converting the robot’s motions into practical tasks.

End effectors made from TPU can absorb shocks and vibrations, protecting both the robotic system and the objects being manipulated. In applications, including assembly and packaging, this property is essential to extend the lifespan of robotic components.

In the medical field, TPU is used to create wearable robotic devices that assist with rehabilitation and mobility. For instance, a study published in

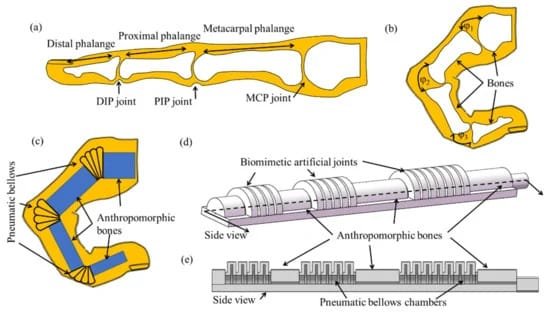

Polymers described the development of a 3D-printed soft pneumatic robotic digit made from TPU. The purpose of the design was to mimic human finger actions. This digit, equipped with pneumatic bellows actuators, can restore finger functions for individuals with trauma or neurological impairments. The TPU-based joints achieve bending angles comparable to human fingers, demonstrating the material’s potential in medical rehabilitation. For instance, the digit’s distal, proximal, and metacarpal joints reach bending angles of 107°, 101°, and 97° respectively.

Finger structure and soft robotic digit structure: bone structure of a human finger in (a) extension and (b) flexion; (c) soft robotic digit mimicking finger flexion; (d) soft robotic digit with biomimetic artificial joints and (e) side view.

Image Credit: Polymers

Moreover, the lightweight nature of TPU minimizes strain on the user and enhances comfort, making it particularly ideal for applications like exoskeletons where weight can significantly impact usability. With a heightened range of motion, TPU material paves the way for future research and application in developing soft robotics for medical use.

TPU’s high elongation at break and rebound resilience makes it ideal for soft actuators, which are components that convert energy into motion. Unlike traditional rigid actuators, which rely on motors and gears, soft actuators are deformable materials to achieve actuation. These actuators can bend, stretch, and compress, allowing soft robots to perform tasks that rigid robots cannot. Research from

Frontiers in Robotics and AI highlights the use of TPU in creating advanced soft actuators that enable robots to perform delicate tasks with high precision and adaptability.

TPU’s unique properties make it an invaluable material for soft robotics. Its combination of flexibility, strength, and durability allows for the creation of advanced robotic components that can perform complex tasks with precision and reliability. The use of MJF 3D printing technology further enhances the capabilities of TPU, offering fast production speeds and consistent quality. As the fields of robotics and automation continue to evolve, the role of TPU in developing innovative and efficient solutions will undoubtedly expand, driving progress and innovation in these industries.