Functional 3D Printed Automotive Parts

Bridge the gap between rapid prototyping and production-grade automotive parts with Endeavor 3D’s additive manufacturing solutions. We utilize a combination of specialized polymer 3D printing materials and Multi Jet Fusion technology to overcome design constraints, minimize part weight, and expedite your product’s market launch. Our end-to-end services help automotive engineers and manufacturers seamlessly transition from concept validation to production-ready components with improved agility, lower costs, and no tooling limitations.

Why Endeavor 3D for Automotive Solutions?

End-to-End 3D Printing Solutions for Automotive Manufacturing

Endeavor 3D simplifies the journey from initial design and rapid prototyping to production-grade and spare 3D printed automotive parts, providing a seamless manufacturing workflow that accelerates timelines and ensures precision at every stage.

Rapid Prototyping

Bridge Production

Full Production

Jigs & Fixtures

Spares & Repairs

ACCELERATE YOUR IDEAS

Benefits

- Free Quoting

- Quick Design Iterations & Testing

- HP Digital Manufacturing Partner

Our Services

Get A Free Quote- Design for Additive Manufacturing (DfAM)

- FDM 3D Printing

- 2D to 3D File Conversion

SCALE WITH CONFIDENCE

Benefits

- DfAM Validation Before Full Production

- Consistent Part Quality

- Zero Tooling Requirements

Our Services

Get A Free Quote- 100% Part Inspection

- PPAP Quality Services

- Vapor Smoothing & Dyeing

STREAMLINE MASS PRODUCTION

Benefits

- Lower Cost-Per-Part

- Flexible, On-Demand Production

- Customization At Scale

Our Services

Get A Free Quote- Multi Jet Fusion

- Metal Jet

- Automated Post Processing

GET CUSTOM JIGS & FIXTURES

Benefits

- Cost Effective Batch Production

- Lightweight Ergonomic Tools

- Simplified Fixture Designs

Our Services

Get A Free Quote- Part Assembly

- Part Consolidation

- Fit and Function Testing

REPAIR WITH EASE

Benefits

- 3D Scanning For Legacy Part Production

- Minimize Equipment Downtime

- On-Demand Manufacturing

Our Services

Get A Free Quote- Reverse Engineering

- Digital Part Storage

- Flexible & Chemically-Resistant Materials

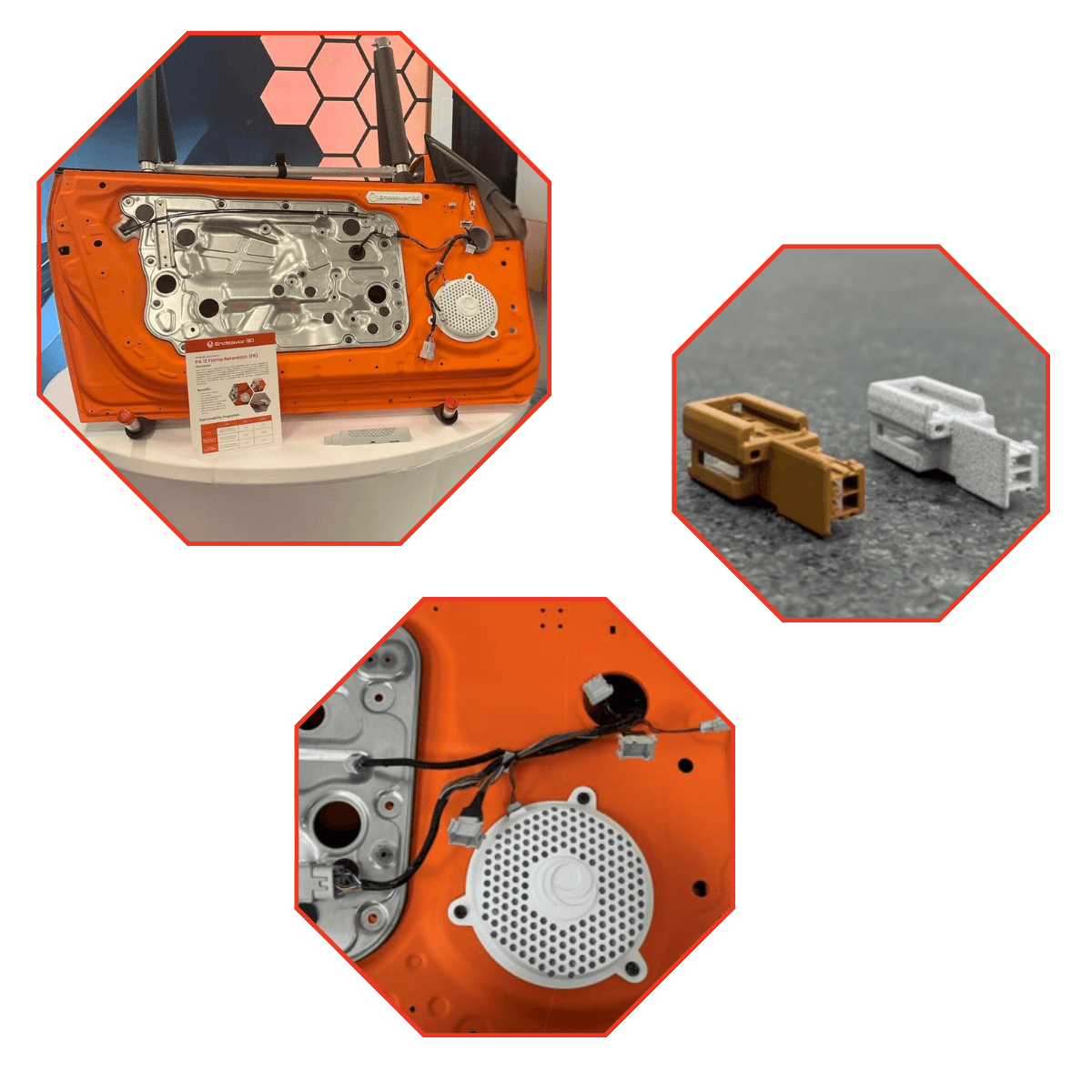

Flame Retardant 3D Printed Car Door Components

Multiple car door parts, including wire harness connectors, electrical housings, and a speaker cover, were 3D printed using Nylon PA 12 Flame Retardant (FR).

By doing so, Endeavor 3D was able to:

- Scan, reverse engineer, 3D print, and install the car door components within 24 hours.

- Comply with the stringent burn resistance standards outlined in the Federal Motor Vehicle Safety Standards (FMVSS) N0. 302 (Flammability of Interior Materials).

- Create digital files for quick design modifications and repeatable 3D printing.