5 Questions to Ask Before Using Additive Manufacturing

Additive manufacturing (AM) has transformed how we manufacture parts, offering design freedom, faster lead times, and scalable production. However, like any manufacturing method, success begins with preparation. By evaluating your project’s specific requirements, you can avoid bottlenecks that may arrive later in the manufacturing process.

To guide you through this process, we’ve identified five critical questions to ask before integrating AM into your production workflow.

1. What are the pain points with your existing manufacturing method?

Pinpointing these pain points helps paint a clearer picture of where AM can be leveraged to overcome specific challenges. For example, AM eliminates tooling requirements, enabling cost-effective low-to-mid volume production. However, this analysis might also reveal that AM isn’t the right fit for your project’s needs.

This evaluation is vital for setting clear expectations and ensuring AM is applied where it provides the most value. This clarity will set the stage for a successful transition to the next question: what criteria to consider when choosing an AM technology?

2. What criteria should I consider when selecting a technology?

For example, if rapid prototyping is a priority, lower-cost technologies like FDM or SLA may be suitable. However, they may not offer the same quality, material properties, or precision as more advanced options like Multi Jet Fusion (MJF) or Selective Laser Sintering (SLS). Cost is another key factor—AM can be cost-effective for low-to-mid-volume production runs (100s and 1000s of parts) but may not always be the best for super high-volume runs (100,000s and 1,000,000s of parts). Prioritizing your requirements will help you more easily determine your scalability requirements.

3. What are your volume and scalability requirements?

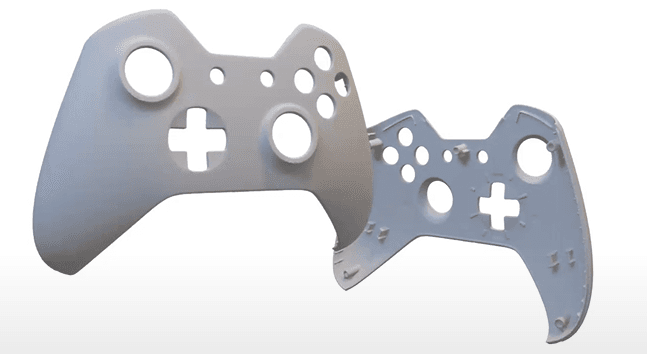

Video game controller housing 3D file

4. Is the part printable or do we need to implement Design for Additive Manufacturing (DfAM)?

The importance of aligning your internal processes and standards with your customer’s project requirements is particularly imperative during this phase in additive manufacturing. Oftentimes, designs require modifications to reduce the risk of warpage or improve structural integrity. Addressing these challenges during the design phase can prevent costly delays and ensure a seamless transition from concept to production.

5. What secondary processes are required?

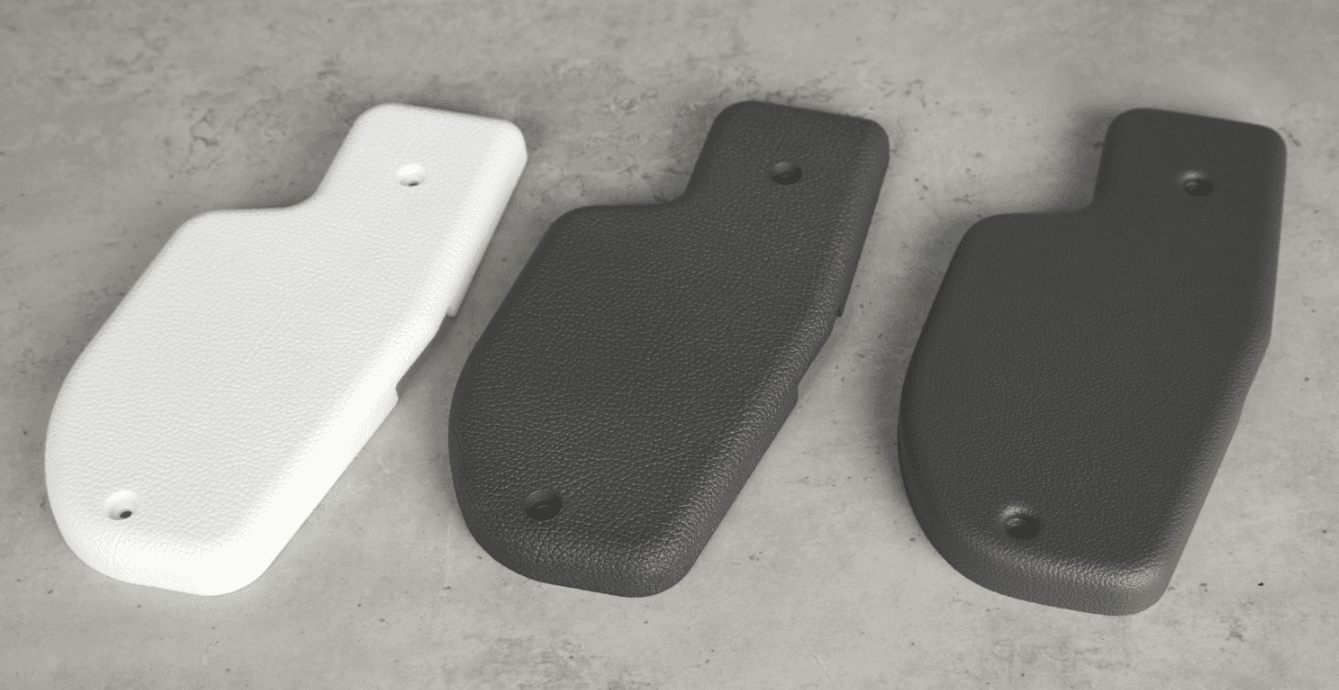

For example, vapor smoothing can reduce surface roughness, but the heat involved might affect material properties. Similarly, dyeing can enhance aesthetics but may add time to the production schedule. Understanding how post-processing affects the quality and variability of your parts helps you select the most appropriate techniques for your needs.

3D-printed automotive spare parts with textures. Courtesy: DyeMansion

Conclusion

Contact us today to discuss your specific needs and explore how we can support your next project.