Stainless Steel 316L

Stainless Steel 316L

Get a Free Quote Request a 3D FileISO 9001: 2015 Certified | ITAR Registered | CAGE Code: 9C1Z8

Stainless Steel 316L

A non-magnetic stainless steel 3D printing material with resistance to high temperatures and corrosion.

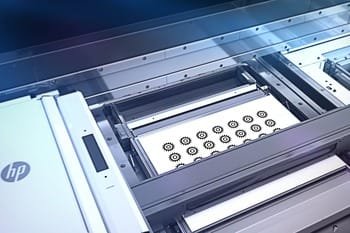

Technology:

Metal Jet

Collaborating with Industry Leaders

ITAR Registered

Endeavor 3D is ITAR registered, enabling us to work on projects involving defense-related articles and services. This certification ensures that all our processes and technologies comply with the stringent U.S. government regulations.

Resources

Have Further Questions?

Talk with a 3D printing engineering expert!