Certifications:

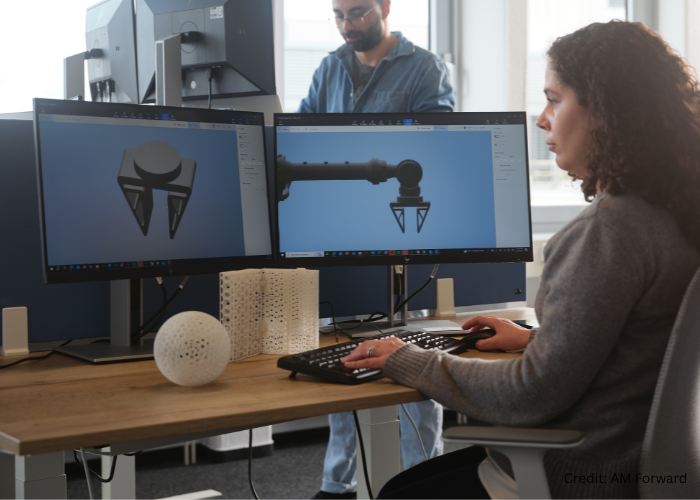

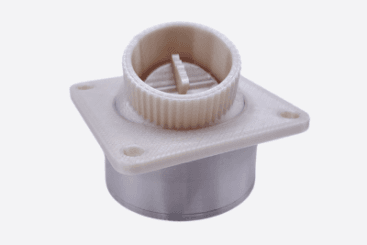

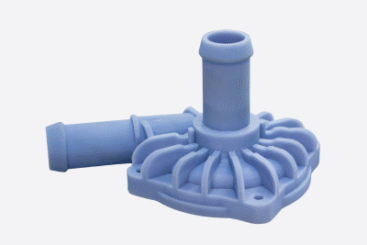

Harnessing the power of polymer and metal additive manufacturing for high-quality 3D-printed parts.

Get a Free QuoteITAR

ISO 9001:2015

3D Printing for Rapid Production

|

|

Made in the USA

Technologies

✓

6 polymer and metal 3D printing technologies

✓

40+ 3D printing material and finishing options

✓

Dimensional and visual quality inspections

✓

Your partner from prototyping to productionOur 3D Printing Technologies

Not sure which 3D printing technology is the correct one for your project? Contact one of our 3D printing experts for best practices.

Available 3D Printing Materials

Polymer Materials

- ABS-ESD7

- ABS-M30

- ABS-M30i

- ANTERRO 800NA

- ASA

- General Purpose Resin V5

- Nylon 12CF

- Nylon 6

- PA 11

- PA 12

- PA 12 FR

- PA 12 S

- PA 12 W

- PC

- PC-ABS

- PC-ISO

- SLS FR-106

- SLS Nylon 12

- SLS PK 5000

- SLS PPS-GF

- SOMOS BioClear

- SOMOS NeXT

- SOMOS WaterShed Black

- SOMOS WaterShed XC11122

- ST-130

- ULTRASINT TPU01

- ULTEM 1010

- ULTEM 1010 CG

- ULTEM 9085

- ULTEM 9085 CG

Polymer 3D Printing Materials

▼

Metal Materials

- Stainless Steel 316L

- Stainless Steel 17-4PH

- Maraging Steel MS1

- Inconel 718

- Aluminum AlSi10Mg

- Titanium Ti6Al4V

Metal 3D Printing Materials

▼

3D Printing Applications

Endeavor 3D is committed to guiding your project from initial concept through prototyping to final production, ensuring seamless transitions and top-quality results at every stage of the product lifecycle.

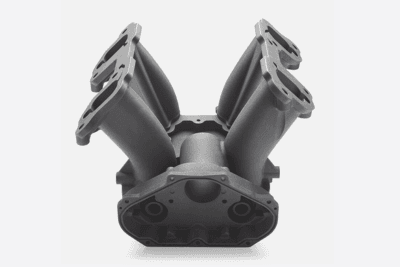

Rapid Prototyping

Bridge Production

Full Production

Jigs & Fixtures

Spares & Repairs

ACCELERATE YOUR IDEAS

Benefits

- Free Quoting

- Quick Design Iterations & Testing

- HP Digital Manufacturing Partner

Our Services

Get A Free Quote- Design for Additive Manufacturing (DfAM)

- FDM 3D Printing

- 2D to 3D File Conversion

SCALE WITH CONFIDENCE

Benefits

- Market Demand Agility & Scalability

- Lower Capital Investments

- Zero Tooling Requirements

Our Services

Get A Free Quote- 100% Part Inspection

- Quality Documentation

- Vapor Smoothing & Dyeing

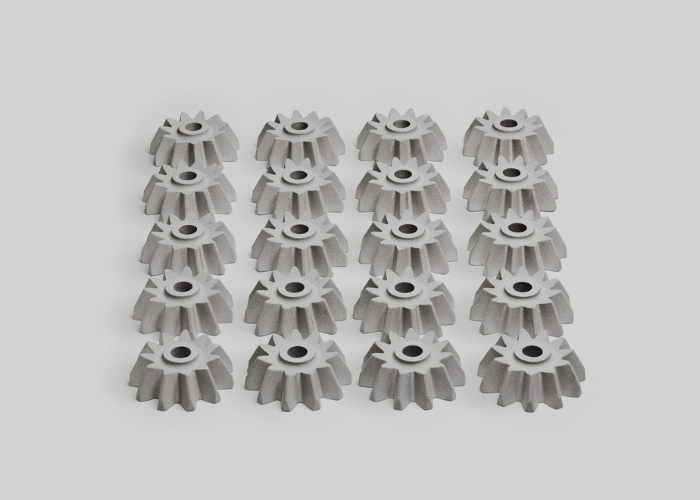

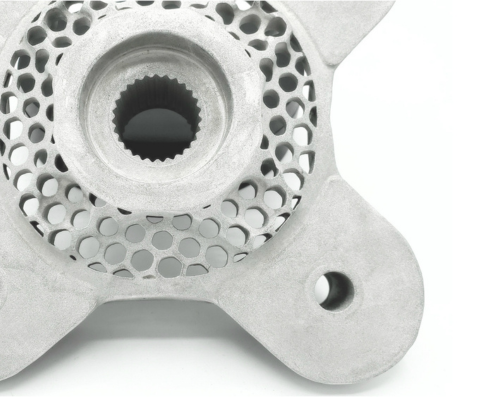

STREAMLINE MASS PRODUCTION

Benefits

- Lower Cost-Per-Part

- PPAP Quality Services

- Customization At Scale

Our Services

Get A Free Quote- Multi Jet Fusion

- Metal Jet

- Automated Post Processing

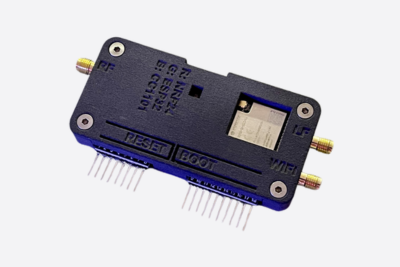

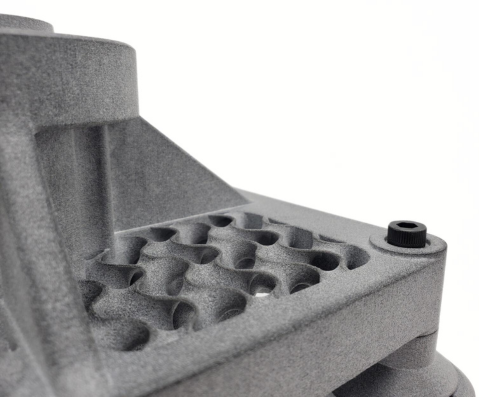

GET CUSTOM JIGS & FIXTURES

Benefits

- Cost Effective Batch Production

- DfAM For Lightweight And Improved Ergonomics

- Polymer And Metal 3D Printing

Our Services

Get A Free Quote- Multi Jet Fusion

- Part Consolidation

- Part Assembly

REPAIR WITH EASE

Benefits

- 3D Scanning For Legacy Part Production

- Minimize Equipment Downtime

- On-Demand Manufacturing

Our Services

Get A Free Quote- Reverse Engineering

- Digital Part Storage

- Flexible & Chemically-Resistant Materials