Solving Obsolescence: Reverse Engineering Spare Parts

What is Reverse Engineering?

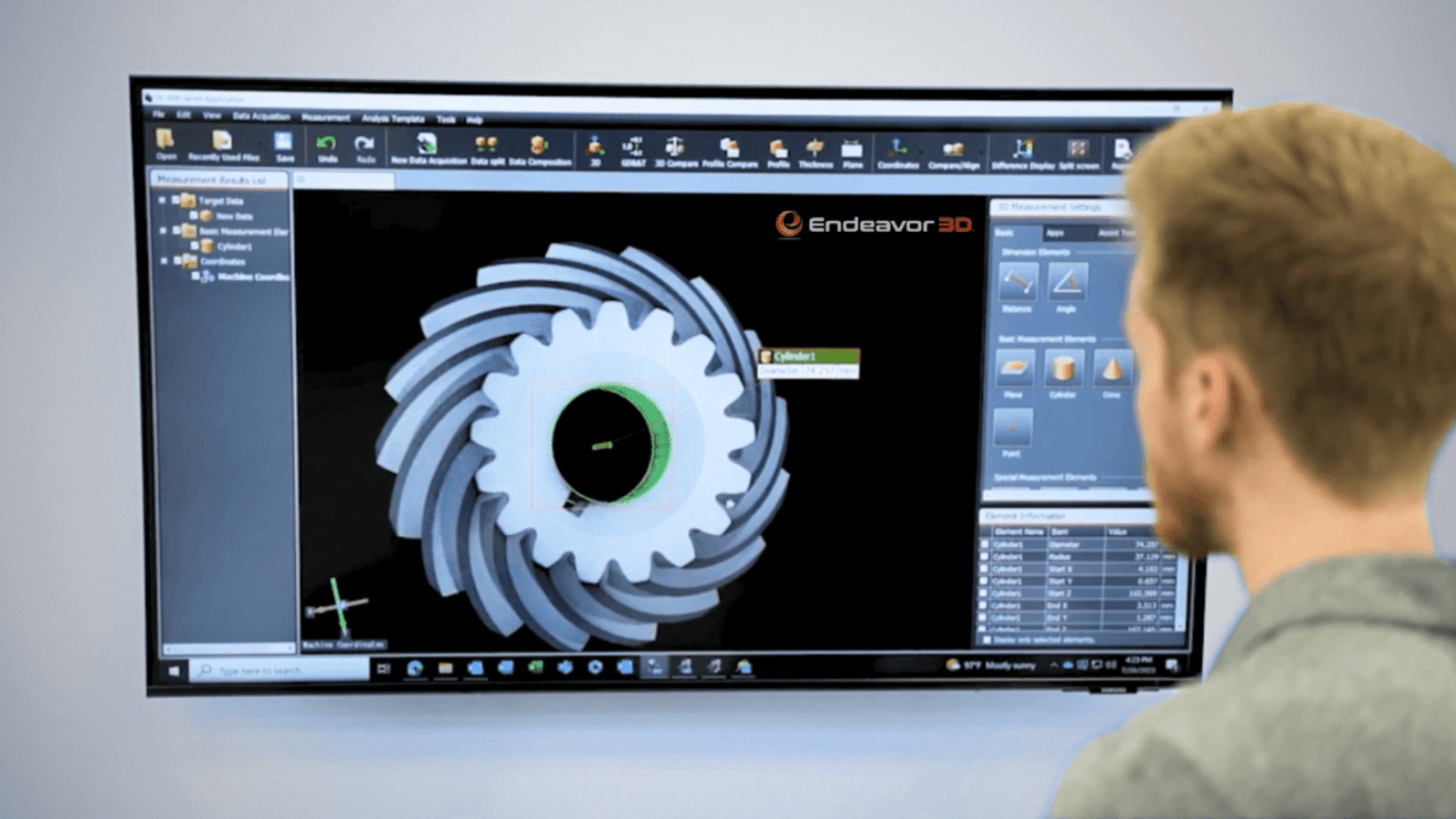

Historically, reverse engineering was labor-intensive, requiring hand-drawn schematics and extensive manual measurements. Today, digital tools such as 3D scanning and CAD modeling have transformed it into a precise and efficient workflow. Modern reverse engineering can recover both simple and complex parts—even those with internal channels or freeform surfaces. The ultimate goal is to produce a production-ready CAD model that accurately reflects the original component, complete with the correct dimensions, tolerances, and geometries for manufacturing.

Endeavor 3D’s Reverse Engineering Services

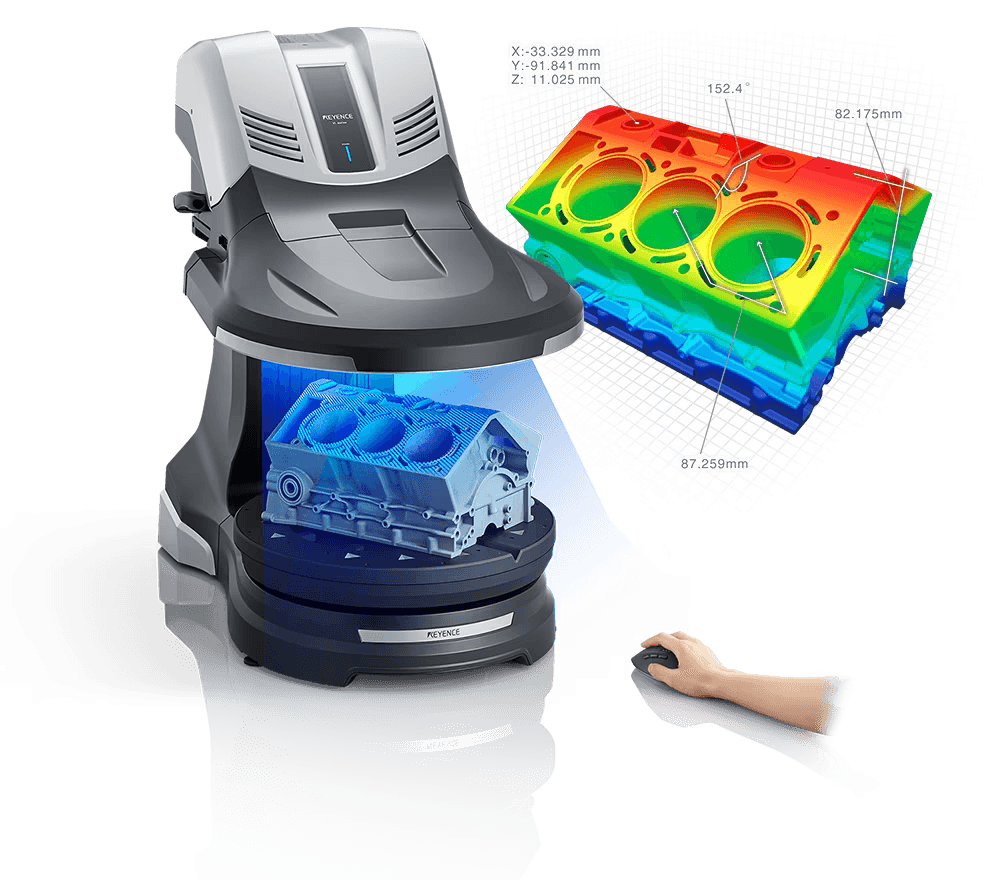

Our team utilizes the Keyence VL500 3D scanner, capable of capturing millions of data points with a resolution of 0.004 inches —”reconstructing components with up to 95% accuracy,” says Endeavor 3D’s Daniel Baker.

Keyence VL500 3D Scanner. Credit: Keyence

The Role of Additive Manufacturing

Additive manufacturing is especially well-suited for complex geometries and internal features that would be costly or impossible to produce using conventional techniques. Spare parts that incorporate channels, undercuts, or integrated components can be produced in a single build.

For industries managing legacy systems or distributed equipment, the ability to manufacture parts on demand with limited minimum order quantities is a game-changer. AM eliminates excess inventory and produces parts at the precise time they’re needed, whether for a decade-old aerospace bracket or a one-off industrial fixture.

Endeavor 3D Additive Manufacturing Services

We offer a portfolio of MJF polymer materials to meet a range of performance, regulatory, and durability requirements:

Nylon PA 12:

Applications: Housings, brackets, enclosures, mechanical fixtures

Nylon PA 12 S (Smooth):

Applications: Jigs, fixtures, aesthetic covers, and medical device parts

Nylon PA 12 White:

Applications: Medical enclosures, biocompatible parts, fluid connectors

Nylon PA 12 Flame Retardant (FR):

Applications: Aircraft interior parts, electrical housings, robotic components

Nylon PA 11:

Applications: Snap-fits, clips, impact-resistant spare parts

Thermoplastic Polyurethane (TPU):

Applications: Seals, gaskets, orthotics and prosthetics, and protective covers

Key Benefits: Reverse Engineering and Additive Manufacturing

1. Cost Reductions and Supply Chain Resilience

Furthermore, reverse engineering can secure a more cost-effective supply chain. This is particularly evident in the Department of Defense (DOD), where “military assets are often operational for decades and a single contractor sometimes supplies the parts needed to sustain them,” according to the U.S Government Accountability Office (GAO). Oftentimes, the original suppliers for spare parts no longer exist or are no longer under contract, leaving the Defense Logistics Agency (DLA) dependent on a single-source supplier, increasing costs. As a result, the DLA has used reverse engineering to regain control over parts sourcing.

2. Enhanced Part Design

3. Shortened Development Cycles

Reverse engineering combined with additive manufacturing dramatically reduces development timelines—especially in sectors like aerospace and agriculture, where legacy equipment must be kept operational despite the absence of original tooling or a reliance on long-standing, and sometimes unstable, supplier relationships.

Instead of waiting weeks or months for a single-source supplier to reproduce a part—or worse, discovering that the supplier no longer exists—engineers can capture the physical geometry of the existing part using 3D scanning tools and convert it into a production-ready CAD model. This model can then be modified, improved, or printed as-is using AM, often within days.

A primary benefit of this digital-first workflow is the repeatability of the process. The production-ready CAD file is stored in a secure digital warehouse, allowing the part to be reproduced on demand without the need to restart the reverse engineering process.

Conclusion

When paired with additive manufacturing, this approach becomes even more powerful. Engineers can not only recover obsolete parts but also enhance them using DfAM principles and advanced 3D printing materials and technologies.

In industries where equipment longevity is critical and downtime is costly, reverse engineering and AM offer a proactive, future-ready solution. Ready to bring legacy parts back to life? Connect with Endeavor 3D to explore how reverse engineering and additive manufacturing can solve your obsolescence challenges with speed, precision, and confidence.