Exploring the Future of Manufacturing: Metal Binder Jetting

The world of manufacturing is evolving rapidly, driven by cutting-edge technologies that promise to reshape how we produce everything from complex parts to final products. One of the most exciting advancements in this space is metal binder jetting—a 3D printing technology that combines the power of additive manufacturing with the...

Designing 3D Printed Hinges and Interlocking Components

The ability to produce fully functional assemblies in a single step is one of the unique benefits of 3D printing. By leaving small gaps in the 3D designs of Multi Jet Fusion parts, interlocking and moving components are produced right out of the machine. These can range from single-axis rotation,...

2024 Additive Manufacturing Survey Report

Additive manufacturing (AM) is evolving from a basic prototyping tool into a full-scale production workhorse. In our latest industry survey, 60% of respondents use 3D printing for end-use parts, up from 35% in 2023. Companies across industries are seeking flexible and scalable solutions to overcome traditional constraints including design limitations...

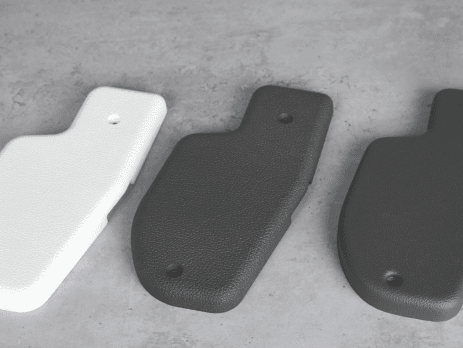

MJF Texturing: Improving 3D Printing with Aesthetics and Function

Apple was one of the companies that put the aesthetics of its products on an equal plane with the functionality of its products. When they were competing for market share in the 90s and 2000s, iconic design and a better user experience helped establish them as one of the most...

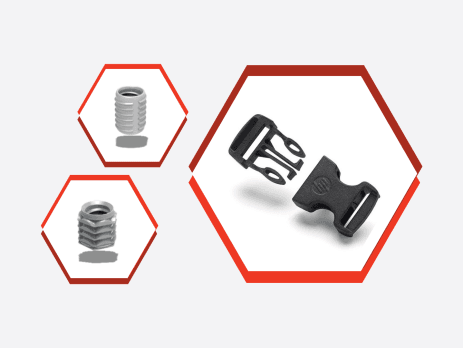

Designing 3D Printed Parts with Inserts, Threads, and Snap Fits

As 3D printed parts become more commonplace in industrial applications, functional integration is becoming increasingly important. A secure mechanical attachment to the larger system is one of the key success factors. With a secure attachment, the part—and the entire system—gains strength and reliabilityOver the past five years, there have been...

3D Printing Workflow for Orthotics and Prosthetics

The prosthetic and orthotic (O&P) industry is at a pivotal crossroads. On one side, the traditional fabrication method relies on manual craftsmanship, involving plaster casting, hand molding, and extensive trial-and-error adjustments. While effective to some degree, this approach is time-consuming, labor-intensive, and prone to inconsistencies. Conversely, you have "off-the-shelf" O&P...