PA 12 S

First Contract Manufacturer in the US to Offer PA 12 S

As the first contract manufacturer in the United States to offer PA 12 Smooth (PA 12 S), Endeavor 3D positions itself as a leader in sustainable and high-quality additive manufacturing (AM) solutions.

In partnership with HP Multi Jet Fusion (MJF) technology, this material brings forth a new era of optimized production processes, significantly reducing variable costs per part by up to 25%.

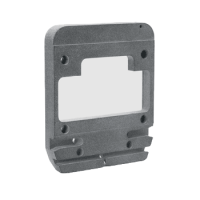

Premium Surface Finish

PA 12 S produces smooth, uniform surfaces. The material improves linear roughness by 70% compared to PA 12, providing premium surface aesthetics for various applications including:

Industrial

Consumer Goods

Automotive

Medical

High Reusability PA 12 S

PA 12 S represents a significant leap forward in sustainable manufacturing practices. With an industry-leading reusability ratio of up to 85%, PA 12 S surpasses all other PA 12 materials in the market.

This effort to minimize material waste and embrace recyclability reinforces Endeavor 3D’s commitment to environmental stewardship. By harnessing the power of HP’s MJF 3D printing technology and PA 12 S, Endeavor 3D promotes a more efficient material powder management process.

Streamlined Workflow

The material’s high refresh rate of up to 85% minimizes waste throughout the manufacturing process. This enables Endeavor 3D to optimize material usage and maximize resource efficiency, lowering cost-per-part for customers.

This efficient material distribution method, combined with the robust mechanical properties of PA 12, opens the door for less restrictive projects that require complex geometries and quick turnarounds.

Mechanical Properties

| Properties | Metrics | Method |

|---|---|---|

| Tensile Strength XY (MPa) | 45 | ASTM D638 |

| Tensile Strength Z (MPa) | 43 | ASTM D638 |

| Elongation at Yield XY (%) | 10 | ASTM D638 |

| Elongation at Yield Z (%) | 6 | ASTM D638 |

| Elongation at Break XY (%) | 12 | ASTM D638 |

| Elongation at Break Z (%) | 6 | ASTM D638 |

| Impact Strength XY (kJ/m²) | 3,2 | ASTM D256 |

| Impact Strength Z (kJ/m²) | 2,5 | ASTM D256 |

| Density (g/cm³) | .98 | ASTM D792 |

Dimensional Properties

| Nominal Dimensions | Tolerances for Cpk=1.33 (in mm) | Tolerances for Cpk=1.00 (in mm) |

|---|---|---|

| 0-30mm, XY | ± 0.25 | ± 0.19 |

| 0-30mm, Z | ± 0.42 | ± 0.34 |

| 30-50mm, XY | ± 0.30 | ± 0.23 |

| 30-50mm, Z | ± 0.50 | ± 0.40 |

| 50-80mm, XY | ± 0.37 | ± 0.28 |

| 50-80mm, Z | ± 0.60 | ± 0.47 |

Maximize your production efficiency and part quality with PA 12 S.

PA 11

Where Innovation meets Responsibility

At the core of our mission lies a commitment to sustainable practices and ethical sourcing. We believe that every step along the additive manufacturing process should embrace this effort, including the materials we use.

Partnering with industry leader Arkema, we are proud to offer 3D printing materials that not only meet the highest standards of quality and performance but also align with our values of sustainability. Arkema is renowned for their dedication to sustainable initiatives, from reducing carbon emissions to promoting circular economy practices. By sourcing our materials from these trusted partners, we ensure that every print produced with Endeavor 3D converts raw materials to high-quality, functional parts with minimal waste.

From Plant to 3D Printed Material

Advanced Bio-Circular Material

Polyamide (PA11) is a high-performance polymer known for its excellent chemical resistance, ability to withstand a wide-range of temperatures, and high dimensional stability.

High Performance:

“The unique 11-carbon semi-crystalline structure yields an impressive balance of properties” says Krysten, Business Development Scientist at Arkema. This allows PA11 to hold a low density profile, while maintaining good wear and chemical resistance.

Tensile Strength, Max Load

7542 psi using the ASTM D638 testing method

High and Low Temperature Performance

-40°C / +130°C

Shore Hardness D Rating

80

Bio-Based:

Produced from a renewable source, PA11 is derived from castor beans which have a highly favorable sustainability profile. The beans are crushed to make around 45% oil and 55% cake (fertilizer).

What does that mean for the surrounding environment?

This makes it a profitable solution for local farmers looking for a crop that is easy to trade and can take advantage of marginal soils. The farming process eliminates the need for deforestation and has 70% less biogenic and biomethane impact compared to fossil-based polyamides.

Sustainable Farming:

With 80% of the world’s castor being grown in Gujarat, India, Arkema made it an initiative to start the Pragati Initiative: a project that enables sustainable castor crop production.

As a result:

More than 74,500 tons

of certified castor beans cultivated from 2017 to 2023

Over 7,850 Farmers

have been trained, audited, and certified

Water Consumption

lowered by approximately 21%