8 TPU Material 3D Printing Applications You Need To Know

TPU is a thermoplastic elastomer material with properties ranging between plastics and rubber. The chemical structure of the material consists of alternating lattice sequences of hard and soft segments formed by the reaction of diisocyanate with short-chain diol and diisocyanate with long-chain diol. TPU material is primarily categorized by its high mechanical strength, good abrasion resistance, and high elasticity. In addition, TPU material is highly resistant to oils, solvents, and chemicals, making it an ideal solution for applications exposed to harsh chemical environments.

More specifically, ULTRASINT® TPU01 leverages the advanced capabilities of Multi Jet Fusion (MJF) 3D printing technology. MJF 3D printing offers unparalleled benefits for TPU material, including:

- High Precision and Detail: MJF ensures excellent surface quality and intricate detailing, achieving layer thicknesses as fine as 80 microns and dimensional tolerances within ±0.012 in., ensuring high accuracy.

- Fast Production Speed: MJF 3D printing can produce parts up to 10X faster than SLS 3D, making it ideal for rapid manufacturing and serial production.

- Consistent Quality: MJF provides consistent mechanical properties across builds with a repeatability of ±0.3%, ensuring reliable and repeatable results.

- Efficient Material Usage: MJF 3D printing with TPU material utilizes up to 80% of the material, significantly reducing waste and making it a cost-effective solution.

TPU Material Properties

| Properties | Test Method | X-Direction | Y-Direction |

|---|---|---|---|

| Tensile Strength (MPa) | DIN 53504, S2 | 9 | 7 |

| Elongation at Break (%) | DIN 53504, S2 | 280 | 150 |

| Tear Resistance (kN/m) | DIN ISO 34 - 1, A | 20 | 16 |

| Flexural Modulus (kN/m) | DIN ISO 178 | 75 | 75 |

| Hardness Shore A | DIN ISO 7619 - 1 | 88 | 88 |

| UL Flammability | UL 94 | HB | HB |

| Melting Temperature (°F) | ISO 11357 (20 K/min) | 248 | 302 |

| Rebound Resilience [%] | DIN 53512 | 63 | 63 |

TPU Material Advantages

Shock Absorption

Additionally, ULTRASINT® TPU01 material’s hardness shore rating of 88-90 A strikes a balance between flexibility and firmness, contributing to its effectiveness in reducing impact forces. This material property is critical in applications where maintaining the integrity of the structure while absorbing shocks is essential, such as automotive components and orthopedic supports.

High Elasticity and Rebound

Resistance to Fatigue

Applications of TPU Material:

1.) Medical

Orthotics:

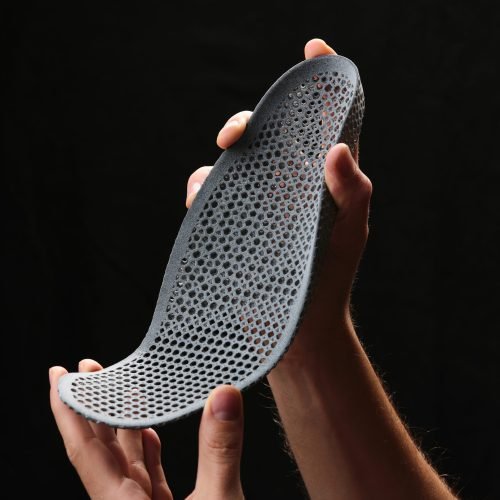

ULTRASINT® TPU01 has a Shore A Hardness rating of 88, providing an ideal balance of stiffness and elasticity to ensure a comfortable, snug fit for insoles. The material exhibits exceptional moisture resistance, preventing the buildup of sweat and bacteria within the insole.

Orthotic printed with TPU01 (Source: BASF)

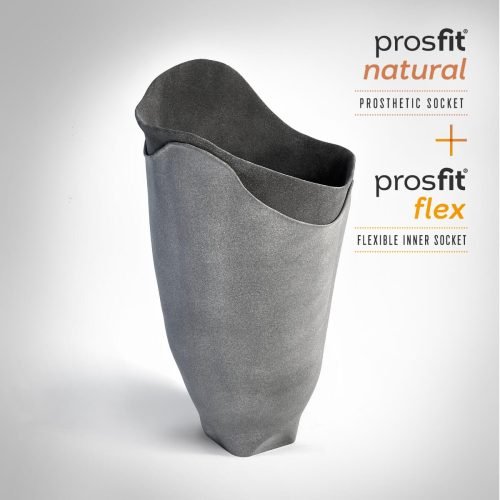

Prosthetics:

BASF proves the validity of this narrative by 3D printing a perfect-fit prosthetic socket for ProsFit using ULTRASINT TPU01 and ULTRASINT TPU88A. Christopher Hutchinson, Co-Founder of ProsFit, says that before starting this project, “producing and fitting the limb required hours of painstaking and cost-intensive manual work by a prosthetics specialist and several visits to the clinic, meaning the whole process could take several weeks. Using Multi Jet Fusion (MJF) 3D printing technology, ProsFit was able to greatly accelerate the design and production process.

The exceptional vibration cushioning and stability under varying, repetitive stress loads enable ULTRASINT TPU to maintain its mechanical characteristics without showing any performance or visual degradation over time.

Prosthetic Socket Printed with ULTASINT TPU01 and TPU 88A (Source: BASF)

2.) Automotive/Transport

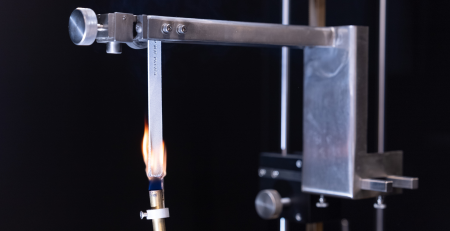

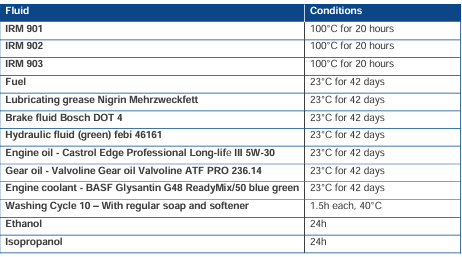

Hoses and Tubes:

ULTRASINT TPU01 chemical resistance chart (Source: BASF)

Source: BASF

Interior Seating:

BASF brings this to light when developing an innovative, open lattice structure car seat design for Citroën. The design provides natural airflow while maintaining the structural integrity to withstand long car rides. Similarly, BASF created car headrests, leveraging TPU material’s elasticity to conform the headrest to a person’s head. This adaptability ensures that the seating remains comfortable regardless of the passenger’s size or seating position, promoting better posture and reducing fatigue.

![Citroën und BASF stellen vollelektrisches Konzeptfahrzeug oli vor / Citroën and BASF unveil electric concept car oli The Citroën concept car oli [all-ë] was designed with BASF materials, some of which are used in radically new contexts.](https://endeavor3d.com/wp-content/uploads/2024/07/P359_Interior_Citroen_BASF_Concept_Car_oli-500x500.jpg)

Car seat printed with ULTRASINT TPU88A (Source: BASF)

Car headrest printed with ULTRASINT TPU01

3.) Consumer Goods

Bike Saddles:

Thanks to additive manufacturing (AM), geometrically complex bike saddles can now be created on a mass-production scale. Combine that with 3D printing TPU material and the result is a bike saddle with excellent long-term shock absorption, energy return, and fatigue resistance.

The material’s flexibility allows for creating comfortable and ergonomic saddle designs that conform to the rider’s body contours. The unlimited design possibilities of ULTRASINT TPU01 enable a more ergonomic saddle design that conforms to the rider’s body contours. The ease of print, high process stability, and high throughput when using Multi Jet Fusion 3D printing technology make it an ideal solution for serial production.

Footwear:

With MJF TPU 3D printing, mass customization is attainable. This is particularly relevant in the made-to-measure orthopedic midsole market where on-demand production is vital.

Moreover, TPU can be manufactured into complex geometries and different levels of flexibility, accommodating the varying design requirements. Its high rebound resilience rate of 63% allows for a more responsive and comfortable consumer experience.

Shoe insole printed with ULTRASINT TPU01 (Source: BASF)

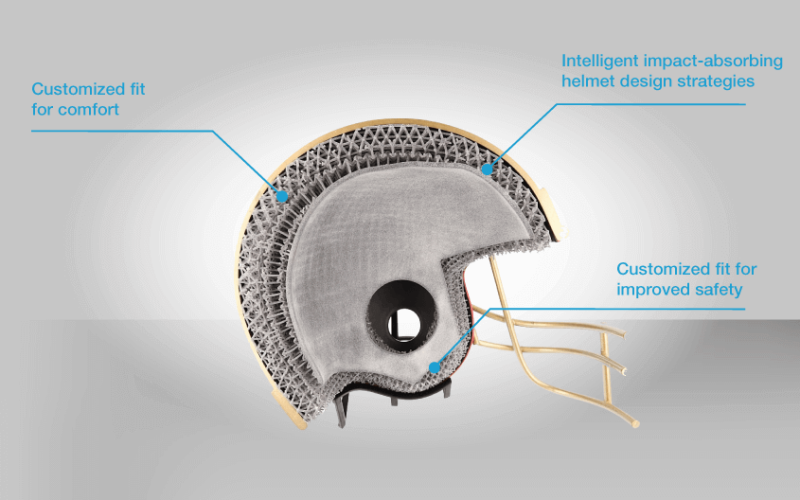

Sporting Equipment:

Flexible lattice structure for shock absorption (Source: BASF)

Internal of helmet printed with ULTRASINT TPU01 (Source: Kupol)

Protective Cases:

Phone case printed with Elastollan TPU (Source: BASF)

Endeavor 3D: Your Partner for TPU 3D Printing Solutions

- Multi Jet Fusion & Metal Jet 3D Printing

- Design and Engineering

- Quality & Validation

- Post Processing

- Reverse Engineering and 3D Scanning

Contact us today to learn more about how you can leverage TPU material for your next project.