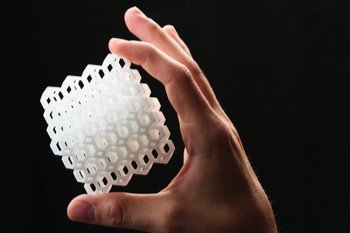

Multi Purpose ULTRASINT® TPU01

The design freedom of TPU material enables rapid iterations and makes it particularly well-suited for mass customization and low-volume production projects. It is commonly used for detailed parts such as sports protection, footwear, orthotics and prosthetics, and automotive interior components.

Collaborating with Industry Leaders

Powered by Multi Jet Fusion

High Precision and Detail: MJF ensures excellent surface quality and intricate detailing, achieving layer thicknesses as fine as 80 microns and dimensional tolerances within ±0.012 in., ensuring high accuracy.

Fast Production Speed: MJF 3D printing can produce parts up to 10 x faster than SLS 3D printing, making it ideal for rapid manufacturing and serial production.

Consistent Quality: MJF provides consistent mechanical properties across builds with a repeatability of ±0.3%, ensuring reliable and repeatable results.

Efficient Material Usage: MJF 3D printing with TPU material utilizes up to 80% of the material, significantly reducing waste and making it a cost-effective solution.

Print high-quality parts with Endeavor 3D using ULTRASINT® TPU01 material and MJF 3D printing technology