Insights from Endeavor 3D’s DfAM White Paper

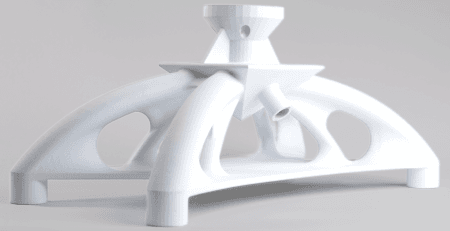

Traditional manufacturing often demands that products be redesigned to streamline production, minimize costs, and eliminate inefficiencies. In AM, this redesign is not just beneficial—it’s essential. DfAM isn’t just about making parts; it’s about creating parts that leverage the unique capabilities of 3D printing, allowing for complex geometries, part consolidation, and material optimization.

One of the central themes of the whitepaper is the decision-making process around whether a particular part should be produced using AM. The answer isn’t always clear-cut and requires careful consideration of cost, performance, and application-specific needs. For instance, part consolidation—where multiple components are combined into a single printed piece—can lead to significant cost savings and product improvements by reducing assembly steps and eliminating potential failure points. This not only lowers production costs but also results in a more robust and reliable product.

The whitepaper also explores the intricacies of optimizing the 3D printing process, from material selection to printing technology. It discusses how choices made at these stages can significantly impact the final product, affecting everything from structural integrity to aesthetic appeal. For example, materials like PA-12 offer precision and resistance to abrasion, making them ideal for certain applications, while more flexible materials like TPU may be better suited for parts requiring durability and flexibility. Furthermore, the efficient use of the print area can dramatically reduce costs by increasing the number of parts produced per setup, as illustrated by a case study within the whitepaper where redesigning a PA-12 bracket nearly doubled production capacity.

Another key insight offered is the importance of the human element in the adoption of AM parts. Even a technically perfect part may face resistance if it doesn’t meet the end user’s expectations. The whitepaper highlights the importance of designing parts that not only function well but also intuitively convey their usability to the people who will work with them. This consideration is crucial for gaining acceptance within organizations that are new to AM technologies.

Endeavor 3D’s whitepaper ultimately emphasizes the value of partnering with experts in the field to navigate the complexities of DfAM. With their deep understanding of AM technology and years of experience, companies like Endeavor 3D can help partners achieve high-quality, cost-effective parts. This whitepaper is an essential resource for anyone involved in additive manufacturing, offering a blend of technical insights and practical advice that will inspire engineers, designers, and manufacturers to take their 3D printing projects from concept to production.

Ready to dive deeper into the world of Design for Additive Manufacturing? Don’t miss out on the full white paper, “From Proof of Concept to Production.” Uncover the insights and strategies that can elevate your 3D printing projects.