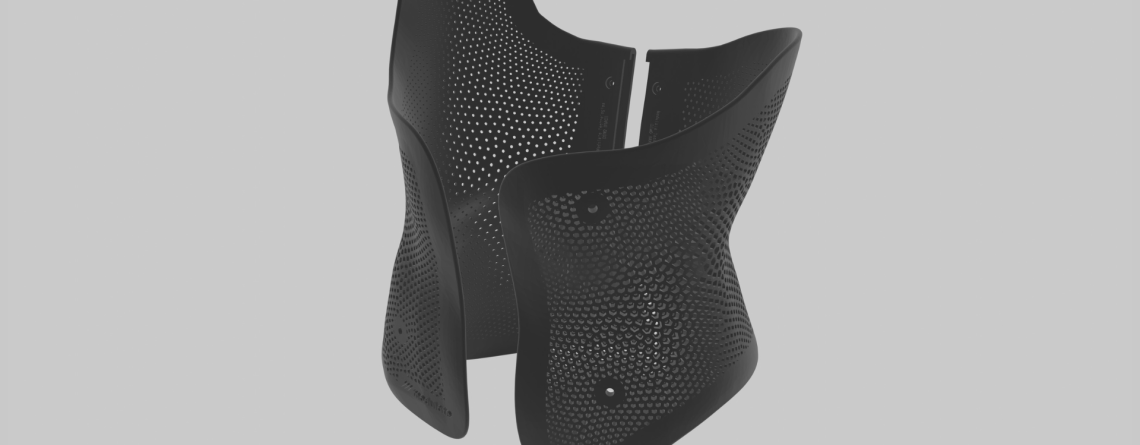

MJF Texturing: Improving 3D Printing with Aesthetics and Function

Apple was one of the companies that put the aesthetics of its products on an equal plane with the functionality of its products. When they were competing for market share in the 90s and 2000s, iconic design and a better user experience helped establish them as one of the most...