Metal Materials

Stainless steel materials that are built to last

Contact UsMetal 3D Printing

It finds its application in various industries such as robotics, automotive, aerospace, medical, and more, where the demand for lightweight, durable, and customizable metal parts is high.

Endeavor 3D's Partners

Excellence through Collaboration

Metal Material Selection

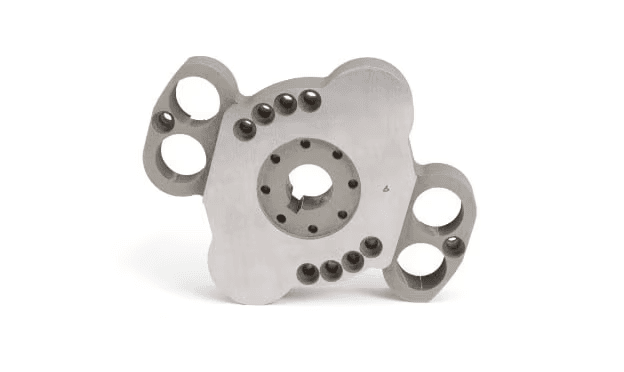

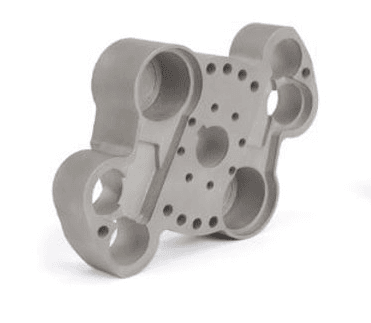

Stainless Steel 17-4PH

A martensite precipitation hardening stainless steel used in applications that require a combination of high strength and mechanical properties with good corrosion and wear resistance. Properties can be tailored through heat treatment, making this versatile material valuable for a wide range of applications.

- Fasteners

- Jigs & fixtures

- Surgical instruments

- Chemical processing parts

Stainless Steel 316L

A non-magnetic austenite stainless steel used in applications requiring extremely high corrosion resistance, excellent elongation, ductility, and strength at elevated temperatures. The high alloy and low carbon content makes it a great fit for variety of applications.

- Heat exchangers

- Medical tools

- Turbine blades

- Mounting brackets

Advantages of Using Endeavor 3D Materials

Here’s what to expect when you partner with Endeavor 3D:

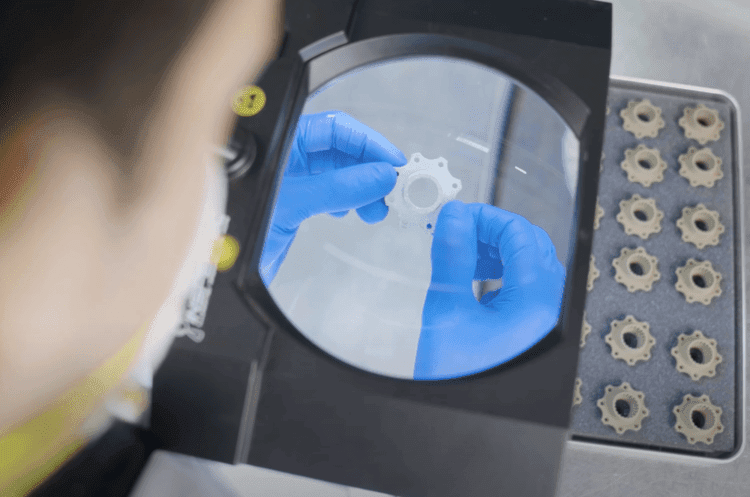

- A Commitment to Quality: Endeavor 3D metal materials are rigorously tested to ensure they meet the highest standards of performance and reliability. By combining our experienced quality control team with a state-of-the-art quality assurance laboratory, you can be confident that every part is thoroughly inspected.

- Expert Support: At Endeavor 3D, we understand that every customer has unique needs and pain points. Choosing the right material for your application is pivotal in delivering meaningful results. Our team of experts will work hard throughout the entire production process to understand all the factors that drive success. That is because we measure our success by your success.

- Versatility: We offer metal materials that suit a variety of applications, from functional prototypes to end-use products. Whether you need a material that is strong and durable, flexible and impact-resistant, or biocompatible, we have the right material for you.

HP Metal Jet S100 3D Printer

Detailed Specifications

17-4PH

| Properties | Test Method | HP Metal Jet (H900) | Benchmark MPIF (H900) | |

|---|---|---|---|---|

| Ultimate Tensile Strength (MPa) | XYZ | ASTM E8 | µ=1277 (min=1261) | ≥1070 |

| Yield Strength (MPa) | XYZ | µ=1152 (min=1136) | ≥1970 | |

| Elongation(%) | XYZ | µ=6% (min=4%) | ≥14% | |

| Surface Roughness (Ra) 2) | XYZ | 7.8 µm (typical) | ||

| Hardness (HRC) | ASTM E18 | µ=40 (min=33) | 35 (typical) | |

| Density | g/cc | ASTM B311 | µ=7.65 (min=7.63) | 7.5 (typical) |

| % | >96% |

316L

| Properties | Test Method | HP Metal Jet (as sintered) | Benchmark MPIF 35 | |

|---|---|---|---|---|

| Ultimate Tensile Strength (MPa) | XYZ | ASTM E8 | µ=561 (min=557) | ≥450 |

| Yield Strength (MPa) | XYZ | µ=227 (min=216) | ≥140 | |

| Elongation(%) | XYZ | µ=61% (min=59%) | ≥40% | |

| Surface Roughness (Ra) 2) | XYZ | 7.7 µm (typical) | ||

| Hardness (HRC) | ASTM E18 | µ=65 (min=56) | 67 (typical) | |

| Density | g/cc | ASTM B311 | µ=7.86 (min=7.84) | 7.6 (typical) |

| % | >96% |