Metal Binder Jet 3D Printing

Creating highly accurate and durable metal 3D printed parts at scale.

Certifications:

ISO 9001: 2015

|

Get A Free Quote arrow_forwardITAR Registered

Call Us arrow_forwardWhat is HP Metal Jet?

This revolutionary technology allows us to craft parts with exceptional detail, consistent quality, and unparalleled speed. At Endeavor 3D, we’ll accomplish what you thought was impossible with the help of our metal 3D printing technology and team of experts.

The Endeavor 3D Metal Jet Process

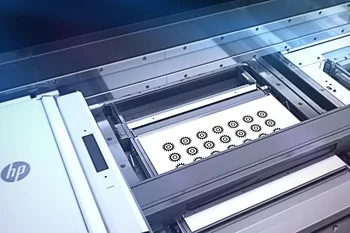

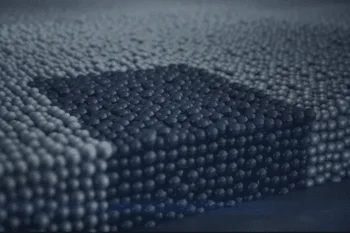

Metal Binder Jetting (MBJ) is a sinter-based additive manufacturing process designed for scalable, production-ready metal parts. Unlike other metal AM technologies limited to prototyping, MBJ achieves high build rates and delivers fully dense parts with properties suited for real-world applications.

During printing, a liquid binding agent is precisely deposited onto thin layers of metal powder to form a “green” part, which is then debindered and sintered to achieve near full-density metal components. The optimal part size for our sintering furnaces is roughly the size of a baseball. However, we have the capability to sinter larger parts with modifications to the cycle length.

From prototyping to short run production, we're here to help transform your vision into tangible results.

Metal Jet Advantages

- Allows for products that support EV’s and ancillary devices for electrification.

- Accelerates product development, improves speed-to-market, and enables “on demand” applications.

- High responsiveness that reduces parts in inventory.

- Personalization and batch production of unique, complex designs.

- Higher efficiency with part performance and longevity with air, liquid, and gas flow applications.

- Eco-friendly due to lower fuel consumption and longer battery ranges.

Metal Materials & Applications

Stainless Steel 17-4PH

High-strength, corrosion-resistant steel with excellent mechanical properties

Stainless Steel 316L

Low carbon, non-magnetic stainless steel that exhibits good strength, fracture toughness, and superior corrosion resistance

Metal Jet General Specifications

Build Platform Volume

Build Speed

Layer Thickness

Learn About Our Adoption of Metal 3D Printing

Watch Tybor Gyorfi, Endeavor 3D’s Metal AM Program Manager, share technical details and a step-by-step guide on how to product consistent, high-quality metal additive manufacturing results.

Any Questions?

Talk with a metal 3D printing expert!