4 Advanced Design for Additive Manufacturing (DfAM) Tips

To develop these next-generation products that can secure market share, we present four advanced design for additive manufacturing toolsets. As highlighted in the previous article, the relatively new technology of 3D printing now has a foundation of design rules, known as DfAM. When followed, these rules virtually guarantee the production of successful parts. These foundational parts solve problems like reliable part supply, low-cost production of low volumes, and simplifying assembly steps. Regarding business strategy, these are important and easily accessible “quick wins.” Integrating one or more of the advanced design principles into the part creates a unique product solution. These become durable products because the advanced design provides performance advantages that cannot be replicated in standard manufacturing but are required for today‘s high-end products.

Using Advanced DfAM for Market Advantage

The next four principles reflect the unique performance advantages that can be gained from additive manufacturing. Many design principles are common to all 3D printing methods that use powder and resin materials. However, HP Multi Jet Fusion offers many “out of the box” advantages based on its unique strengths. Part packing density is among the highest, and combined with the low material price, it makes it one of the most cost-effective production systems. MJF products are waterproof without additional processing, which is critical for routing applications involving water or other fluids. HP recently introduced its improved surface quality with materials that work with fully round powder particles for smoother, customer-ready parts that have the “feel” of injection molding.

Hewlett Packard brings decades of experience to the development of machinery for mass production. Their expertise will help ensure continued price and efficiency gains for years to come. This article provides a basic understanding of these concepts, with more details available in the specially linked explanatory articles.

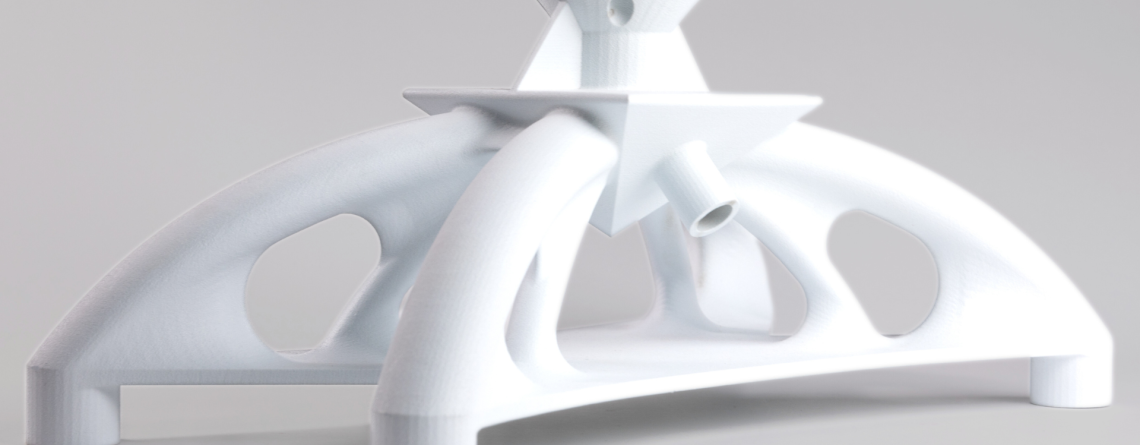

1. Adding “impossible” internal design features in MJF

A few examples:

- Internal channeling allows the flow of liquid or solid materials in a confined space within a complex system (directly leveraging the watertight properties of MJF products).

- Manifold applications to distribute one or more liquid inputs to different output locations with a mixing flow, or distribution block, in the middle of the system.

- Pneumatic tubing in automation and robotics, where internal channeling can distribute air to pick-and-place objects with the flow tailored to the specific application.

- Lightweighting using lattice geometries or finite element analysis to gain speed by using less mass or gain strength by using the same mass more efficiently.

Sometimes the “impossible geometries” can be much more mundane. A typical use case is 3D printing parts without worrying about molding rules and costly processes like MoldFlow analysis or optimizing ribbing for structural integrity. This allows engineers to quickly get their parts into active use in products or machines. As the “first run” parts wear out and reveal problems, design changes can be continually updated at little or no additional cost. Once the design is adequately validated in the field, the customer can further optimize it for 3D printing (which is becoming more cost-competitive with volume manufacturing every year) or invest in adapting the design for injection molding for scale-up applications.

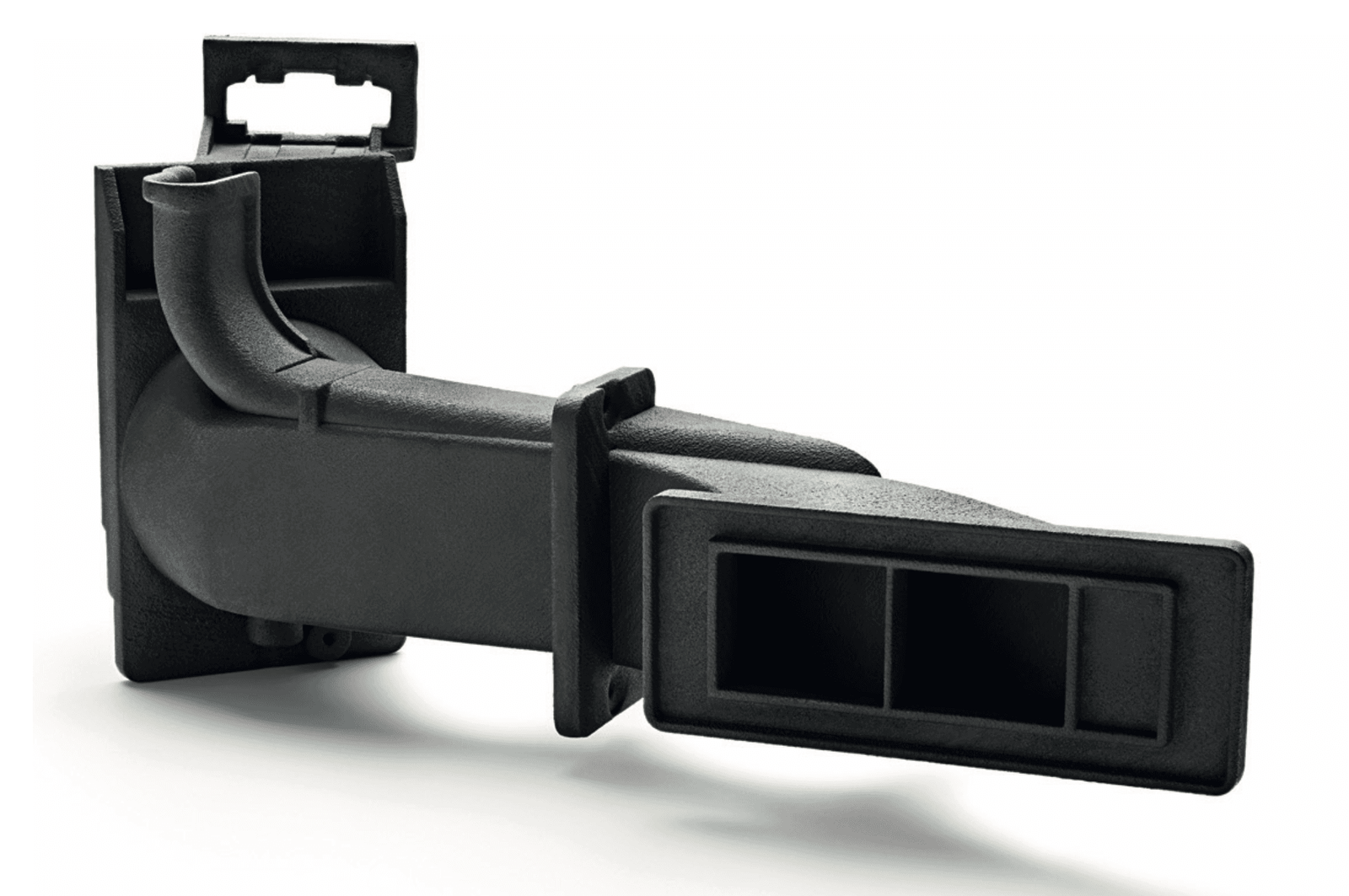

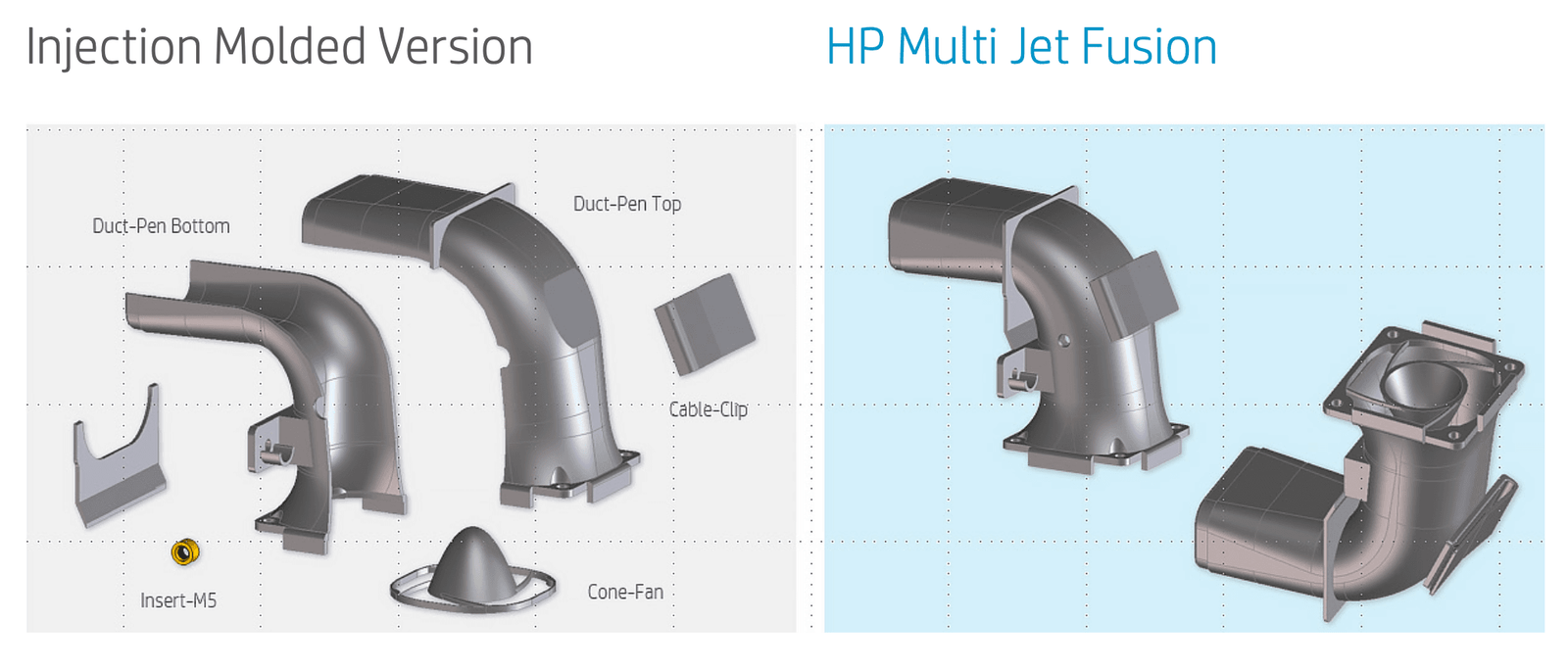

MJF Nylon PA 12 3D-printed duct. Source: HP

3D-printed MJF products do not have to take into account draft angles and other injection molding limitations, so the CAD designer can iterate faster and lower the overall cost. As long as the geometry is open enough for powder removal, engineers also do not have to consider overhangs or even partially enclosed areas that would typically require significant rework of a design to ensure manufacturability.

The unique geometries that tool-less production enables deliver significant speed-to-market and performance benefits. With the next approach of consolidating assemblies, it is possible to double down and achieve even greater gains in produced parts.

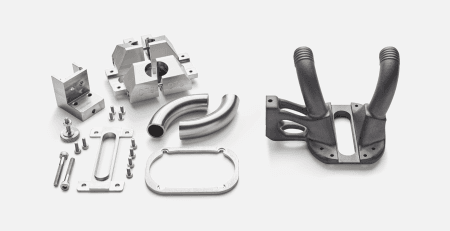

2. Consolidating Assemblies into Single Products

Customer spare parts in machine manufacturing are another typical example. The connection points to pumps or electrical supplies are “standard” design components, and the other geometries can be adjusted per machine to ensure an exact fit in a complex shape or guarantee a second use as a bracket or guide board.

Finally, if certain parts have issues with leakage (air or liquid) due to heat welding or bonding of multiple components, these are also prime candidates for assembly consolidation. The process eliminates the possibility of leakage because there is no seam. The fact that MJF delivers watertight parts is a key performance advantage.

3. DfAM Engineering using Lattice and FEA

Lattice generation is another advanced design for additive manufacturing tool that can provide significant benefits in weight reduction, strength improvement, and load distribution. In many cases, all three aspects can be improved in a single part—a win, win, win. Latticing is also a manufacturing method unique to 3D printing because it requires the production of hundreds or thousands of small boxes (called cells) with solid edges and hollow centers. Often, these structures retain the same strength as the original solid material with better impact absorption. For applications where weight is a significant factor in industries such as robotics, automation, aerospace, and high-performance automotive, working with lattice structures can bring significant improvements to parts.

Aautomotive headrest 3D-printed using MJF and BASF TPU.

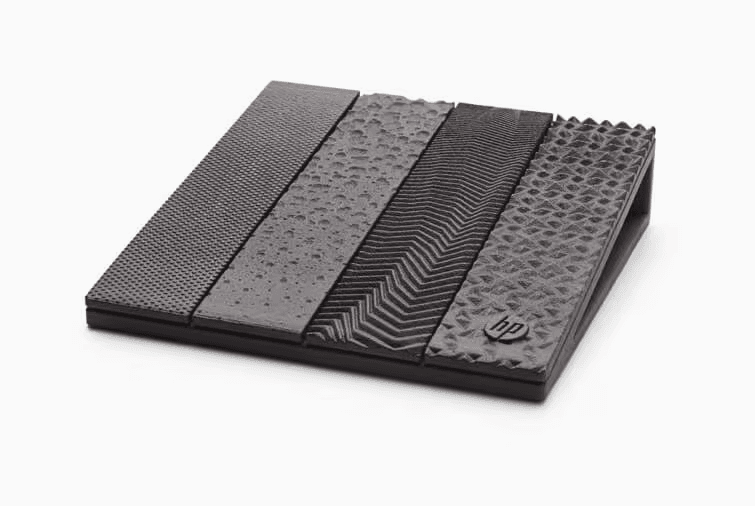

4. Adding Textures for End-Use Products

The final aspect of advanced design for additive manufacturing is the addition of textures to production parts. This is an often overlooked aspect of 3D printing, but one that makes a real difference in adding aesthetic “value” to consumer products. Important functional benefits can also be added to parts with minimal additional effort or cost for adding friction or flow control to a part.

Because 3D printed parts are created directly from digital files rather than from hard tooling, “complexity becomes low cost.” Both free and professional programs are available to select surfaces within an exported design and apply a texture directly to that surface. The texture overlay automatically follows the contours of the product, resulting in compelling designs.

HP 3D printing textures. Source: HP

- Elastic parts using TPU with leather-like surfaces, such as handles or covers

- Replacement parts with textured surfaces similar to the originals in cars or trains

- Custom surfaces with geometric overlays for unique finishes on consumer-facing products

- Adding logos or design elements onto electronic covers to personalize white-label products.

As the saying goes, “quality is in the details,” and adding textures or other surface treatments can make products stand out. Both free and paid software have become very sophisticated in creating these textures; just a few steps can significantly improve the visual perception of the product. Advances in chemical polishing (also known as vapor smoothing) make it possible to treat the surface so that it is almost indistinguishable from an injection-molded part.

Adding texture can also provide specific technical advantages to parts. Placing grains on rubbing surfaces can provide extra friction to ensure the part performs properly in a larger system. An example might be rubber feet in custom shapes placed under a medical testing device. Ridges of varying depths could be added to guide a gripper to the proper attachment points on products. Using chemical smoothing to close all pores in the surface of the parts can make the components usable in applications that require intensive cleaning, such as medical production lines or food processing. By paying attention to the details of the textures, a little extra work in the design phase can often have an outsized impact on the performance of the part.

Advanced Design for Additive Manufacturing Ensures Leading Solutions

Incorporating one or more advanced designs for additive manufacturing principles can create long-term competitive advantages in the marketplace. Having a strong manufacturing partner at your side can provide additional design recommendations or tweaking to make it more scalable. These partners provide access to manufacturing facilities, materials, and expertise that remove traditional barriers to entry for new technologies. Now is the time to follow these principles and start realizing both immediate and long-term value from 3D printing.