3D Printing Mission-Critical Military Parts

Recent investments and initiatives confirm this shift is no longer theoretical but is actively underway. According to AM Research, the DoD spent an estimated $800 million directly on additive manufacturing in 2024. That number is expected to exceed $2.6 billion by 2030. This surge in funding reflects growing trust in AM’s strategic value and its expanding role in the defense supply chain. As outlined in the DoD’s Additive Manufacturing Strategy, the Manufacturing Technology (ManTech) Program is focused on scaling additive technologies across the defense industrial base to accelerate adoption, improve readiness, reduce supply chain risk, and support point-of-need production.

The goal is to accelerate the role of additive manufacturing across defense operations, not just in research labs, but in real-world, mission-ready applications. Two areas where AM is already delivering tangible impact are the rapid deployment of 3D printed drones and the on-demand production of flight-critical and field-repairable parts.

Barriers to Broader Adoption

Training Gaps

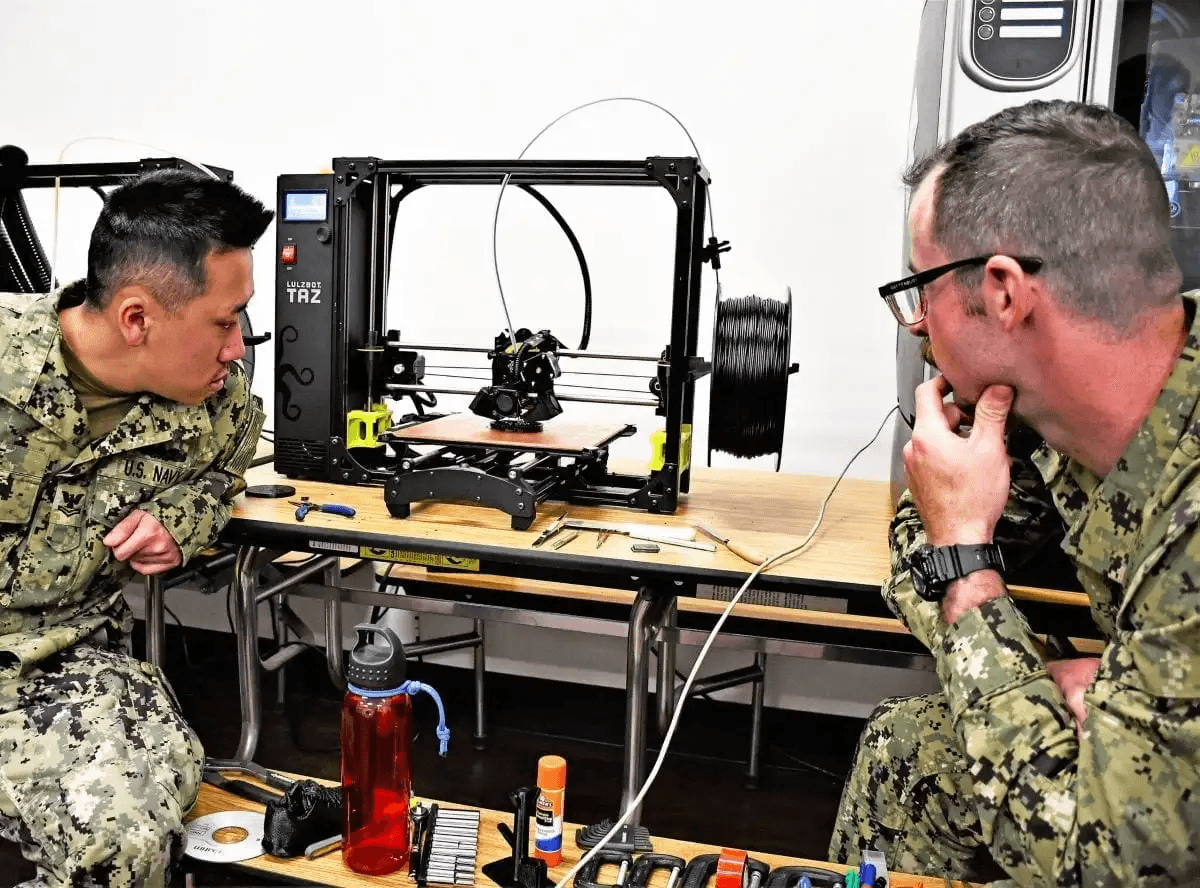

Sailors from the Southwest Regional Maintenance Center printing on an FDM 3D printer. Credit: DefenseMediaNetwork

Certification and Standardization

According to the Institute of Mechanical Engineers, “It currently takes 18 months on average for a supercomputer to evaluate a single 3D part and predict its lifespan or expected date of failure.” However, a DARPA-backed initiative has recently been launched to tackle this exact issue. The program aims to accelerate the certification of 3D printed parts by developing new computational models and material behavior simulations that can predict performance without requiring extensive destructive testing. If successful, this approach could reduce qualification timelines and make it easier to approve AM parts for use in aircraft, vehicles, and weapons systems while maintaining safety and quality.

U.S. DoD Accelerates Low-Cost Drone Production

Defense Secretary Pete Hegseth and Undersecretary of Defense for Research and Engineering Emil Michael at the Pentagon. Credit: Navy Petty Officer 1st Class Alexander Kubitza, DOD

This growing demand is not just about volume; it’s about evolving capability. Modern drones must be agile, lightweight, low-cost, and field-ready within months, not years. This urgency had led to a surge in the adoption of additive manufacturing (AM).

Additive Manufacturing-Enabled Drone Applications

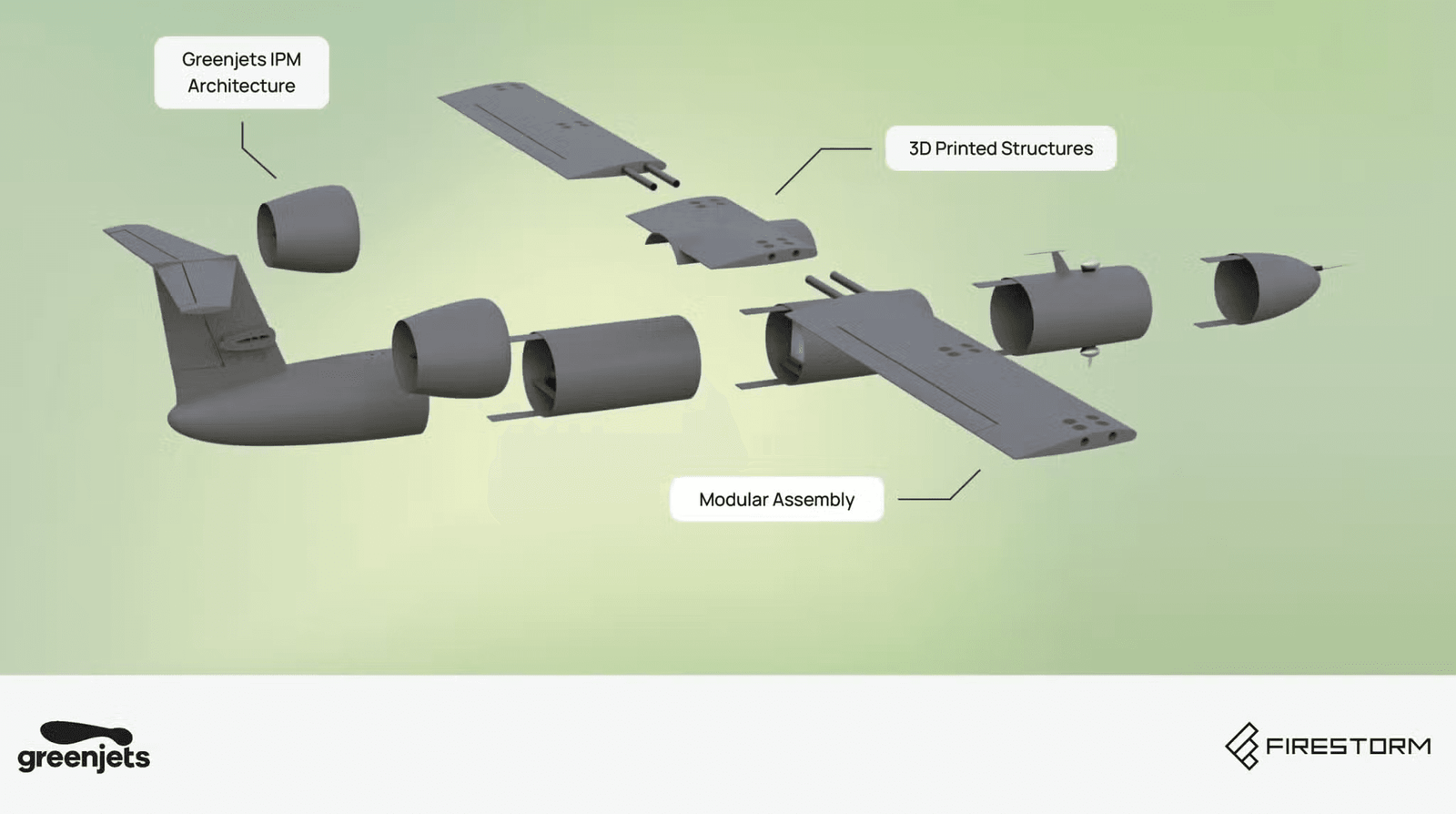

1. Firestorm Labs: First 3D Printed, Modular Warfare Drone

Firestorm’s 25-pound Tempest-25 UAV prototype. Credit: Firestorm

Each Firestorm drone consists of 80% 3D-printed parts, allowing for fast deployment and flexible design updates without extensive retooling. The platform supports swappable payloads, including kinetic and electronic warfare systems, and is intended to counteract mass drone production by foreign adversaries with scalable, lethal alternatives made in the U.S.

Firestorm 3D printed drone. Credit: Firestorm

2. U.S. Army’s 3D Printed Surveillance Drones

These drones are produced using a combination of HP Multi Jet Fusion and Fused Deposition Modeling (FDM) technologies, enabling rapid fabrication of lightweight, mission-specific airframes. Each drone is outfitted with autonomous navigation, on-board AI, and environmental sensors capable of detecting airborne toxins or trace contaminants in real time. The use of AM empowers soldiers to tailor drone designs for aerodynamic performance, payload requirements, and ruggedness, all of which are critical for operating in harsh, contaminated environments. The Army reports these systems can be deployed within

US Army Chief Warrant Officer 2 Chris Lehr prepares the 3D printed drone before flight. Credit: 3Dprint.com

On-Demand Critical Parts

1. Naval Part Maintenance

Submarine and personal protective equipment 3D printed with Multi Jet Fusion. Credit: Shayna Gosney, Navy and Air Force Staff Sgt. Eugene Oliver

According to the 3D Printing Industry, “The U.S. Navy aims to overcome supply chain constraints with point-of-need production by procuring up to 1,600 AM components annually by 2030 and deploying up to 100 large-format wire-based DED metal 3D printing systems.”

2. Deployable 3D Printers for Quick Battlefield Repairs

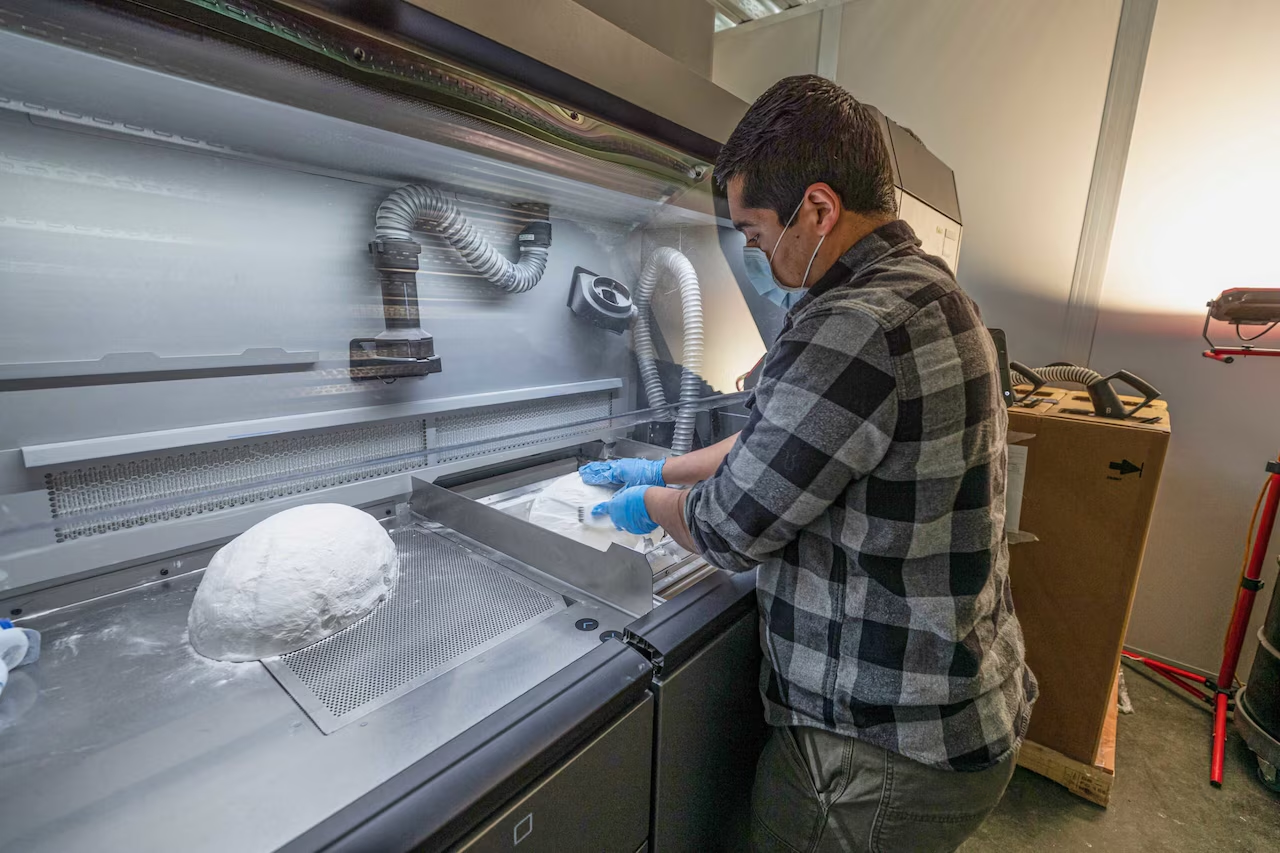

Firestorm Labs is leading this charge with the xCell, a containerized mobile manufacturing unit equipped with semi-automated Multi Jet Fusion (MJF) 3D printers. The XCell allows operators to produce end-use production parts and spare parts in harsh, off-grid environments.

Firestorm’s Deployable xCell container. Credit: Firestorm Labs, Inc.

3. 3D Printing Flight-Critical Military Aircraft Components

To meet the stringent demands of aerospace environments, vendors must demonstrate capabilities across several technical criteria including:

- Rigorous assessment of quality management systems (QMS)

- Material certification and process control

- Additive-aware design and non‑destructive inspection methods

- Full data traceability and cybersecurity compliance (e.g. with DoDI, FAA, ASTM, AS9100)

- Alignment with recognized airworthiness authorities and standards, including ISO 9001 and AS9100

Moreover, the Air Force is emphasizing the importance of digital thread continuity, capturing every stage of a part’s lifecycle from design to deployment. As the ecosystem around metal and high-performance polymer 3D printing matures, this effort reflects a broader defense strategy: to decentralize manufacturing, reduce supply chain risk, and increase fleet readiness through rapid, distributed part production. With successful qualification, additive manufacturing has the potential to transform how the military repairs, replaces, and upgrades vital aircraft components, directly supporting mission continuity in high-tempo or contested environments.

The Future of Additive Manufacturing in Defense

Additionally, the Office of the Secretary of Defense is backing AM through its Additive Manufacturing Innovation project, part of the broader Manufacturing Innovation Institutes (MII) program. America Makes, the flagship institute for AM, is slated to receive $43.7 million to continue driving advancements in defense-grade 3D printing technologies.

As funding and focus increase, the integration of AM into military strategy is accelerating, expanding from point-of-need production and sustainment to the qualification of flight-critical components. These initiatives reflect a long-term vision: using AM not just for rapid prototyping, but for enabling a more agile, distributed, and resilient defense manufacturing ecosystem.

Endeavor 3D is proud to support this vision as an ITAR-registered contract additive manufacturing partner. Our end-to-end 3D printing services have proven to deliver high-quality parts for mission-critical defense applications. Contact Endeavor 3D today to learn how our advanced AM capabilities can accelerate your defense projects and secure your place in the future of military manufacturing.