3D Printing a Myoelectric Bionic Prosthetic Hand

Then a student at the University of Texas at San Antonio (UTSA) studying to become an electrician, Saavedra had always been fascinated by the hand — its mechanical beauty, its expressive subtlety. After rupturing the A2 pulley tendon in his finger and losing the use of his hand for six months, he experienced the emotional and physical toll of reduced mobility firsthand. But for him, that frustration became fuel.

In 2018, armed with yarn, cardboard, a flex resistor, a servo motor, and an Arduino board, he began building his first prosthetic finger — the seed of what would become a game changer in the prosthetic hand industry.

Saavedra’s first prosthetic finger made of cardboard and yarn. Credit: Alt-Bionics

The Problem with Traditional Prosthetics

In his final year at UTSA, he entered a university competition where he presented a prototype of a bionic hand enhanced with AI. It wasn’t just a project — it was a mission. That project caught the attention of Ryan Davis, a former Army Ranger and triple amputee. When Davis tried the hand and it worked, the impact in the room was undeniable.

People turned to Saavedra and asked, “What’s next?”

That moment crystallized what would become Alt-Bionics — not just an engineering venture, but a movement to make high-performance, low-cost prosthetics available to those who need them most.

In 2020, Saavedra graduated and founded the company with a mission to disrupt an industry plagued by high costs, slow repairs, and limited access.

Saavedra’s first prosthetic finger made of cardboard and yarn. Credit: Alt-Bionics

The Genesis Hand: Affordable Innovation

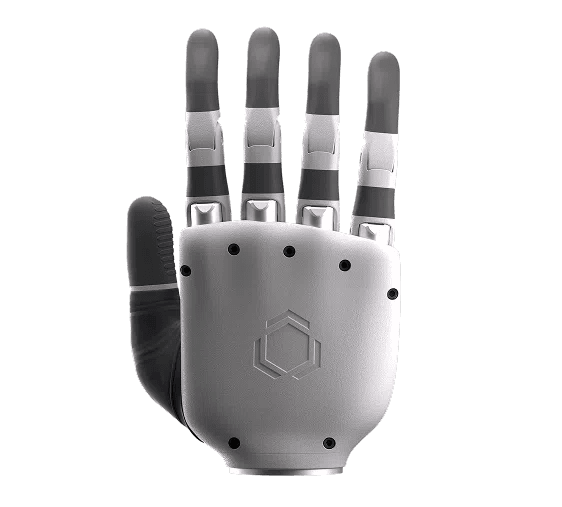

- Thumb rotation and flexion powered by a dedicated palm motor, eliminating manual finger adjustments and movements.

- Visual feedback on the back of the hand displays signal strength and battery life.

- A modular design that includes four spare fingers and a dorsal housing that can be replaced in seconds.

- Lightweight: One of the lightest prosthetic hands on the market, weighing just over 1 pound (1.02 lbs)

- Affordability: Priced at $6,000 — a fraction of traditional alternatives.

However, the breakthrough wasn’t just in the electronics. To make this device viable in real-world use, Alt-Bionics had to rethink how it was made.

Genesis Prosthetic Bionic Hand. Credit: Alt-Bionics

Why 3D Printing?

That’s when 3D printing piqued the interest of Saavedra. He and his team tried FDM, SLA, and SLS 3D printing, but none provided the durability or design flexibility needed. However, they came across Multi Jet Fusion and Nylon PA 12 — a pairing that changed everything.

Failed SLA 3D printing prototype attempt

Genesis Hand 3D printed with MJF 3D printing

- Rapidly test over 67 design iterations with no tooling delays or costs.

- Achieve exceptional strength and flexibility with fingers bending nearly 60 degrees before showing signs of failure.

- Produce complex geometries not possible through traditional means

- Optimize builds with strategic part placement and nesting to reduce costs and improve surface finish

A Partnership That Pushed Limits

As Ryan Saavedra put it:

“Alt-Bionics is able to push the boundaries of prosthetic hand design and hit tolerance levels we didn’t know possible with Endeavor 3D as our production partner.”

Ryan Saavedra, CEO of Alt-Bionics

Building Beyond the Body

Thanks to additive manufacturing’s ability to store CAD files in a digital library, Alt-Bionics was able to adapt the original prosthetic design into a robotic platform without starting from scratch. It was the ultimate proof of concept — that a hand built to restore movement to humans could also shape the next generation of humanoid machines.

Learn more about Alt-Bionics and Endeavor 3D by watching the on-demand webinar →

Alt-Bionics Humanoid Hand. Credit: Alt-Bionics